Article No. 2088830

High-grade, crack-bridging, polymer-modified 2K bituminous thick coating with polystyrene

Product specifications

On delivery

(20 °C/70% relative humidity) < 48 hours

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Waterproofing of new and old buildings with ground contact

- Water impact classes W1.1-E, W1.2-E, W2.1-E, W3-E and W4-E (splashing water only) as per DIN 18533

- Retrofit waterproofing of buildings according to WTA Code of Practice 4-6

- Plinth waterproofing

- Approved for connecting to water impermeable concrete structures

Properties

- Solvent-free

- Water pressure tight

- Highly flexible, elastic and crack-bridging

- General building inspectorate test certificate as per the testing principles for building waterproofing transitions (PG ÜBB)

- Radon-tight (verified through testing)

-

Preparation

-

Substrate requirements

Even-surfaced, mineral substrate.

Clean, dust-free and capable of supporting a load.

Prepare concrete substrates at wall/base transition areas by means of mechanical material removal.

Matt damp surfaces are permitted.

If necessary, provide damp proofing.

-

Preparations

Remove projecting seams and mortar remains.

Break off or chamfer corners and edges.

Smooth out inner corners using a suitable mineral mortar.

Close indentations > 5 mm using a suitable mineral material.

Prime absorbent mineral substrates with Kiesol MB. Prime non-absorbent mineral substrates with BIT Primer[basic] (1:10 in water).

If the substrate requires reinforcement (restoration), prime using Kiesol (1:1 with water).

Create a scratch coat using the product as a contact layer and in order to prevent blisters.

-

-

Preparation

-

Combination container

Break up the powder component before adding to the bitumen emulsion.

Remove any dried material adhering to the edge of the bucket.

Briefly stir the bitumen base material.

Add the entire quantity of broken-up powder component to the bitumen emulsion.

Mix for approx. 30 seconds, stop mixing and allow the air introduced during mixing to escape.

Remove the powder adhering to the side.

Resume mixing and continue for at least 2 minutes.

Leave the anchor stirrer near the base throughout the mixing time.

See mixing instructions.

-

-

Application

-

Apply the product in two layers on the previously prepared substrate.

If a reinforcement fabric is required, embed into the first waterproofing layer.

-

Application instructions

-

In the case of liquid-applied waterproofing materials, direct sunlight and/or wind exposure can cause accelerated skin formation and accompanying blistering.

Do not apply any further layers until the previous layer has hardened sufficiently.

Protect freshly coated surfaces from rain, direct sunlight, frost and condensation.

Protect dry sealant from mechanical damage and UV radiation.

Please contact Remmers Technical Service (phone +49 5432 83900) before applying with machine processing.

-

-

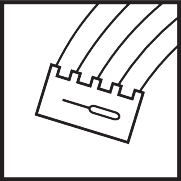

Working tools / cleaning

-

Anchor stirrer, scoop, smoothing trowel, layer thickness trowel

-

Clean tools immediately after use with water.

Remove dried-on material using V 101 Thinner (0978).

-

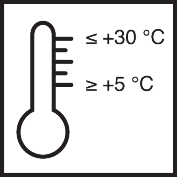

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 12 months.

-

Usage

-

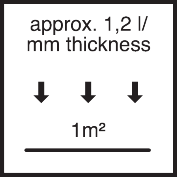

Approx. 1.2 l/m²/mm dry layer thickness

Min. 1.5 l/m² as perimeter insulation adhesive

See application rate table for details

-

Application examples

-

Water impact class

(according to DIN 18533)Dry layer thickness

(mm)Wet layer thickness

(mm)Application quantity

(l/m²)Yield

30 l

(m²)W1-E

Ground moisture and non-pressing water≥ 3 approx. 3.5 approx. 3.5 approx. 8.5 W2.1-E*

Moderate impact of pressing water (immersion depth ≤ 3 m)≥ 4 approx. 4.7 approx. 4.7 approx. 6.4 W3-E

Non-pressing water on earth-covered ceiling≥ 4 approx. 4.7 approx. 4.7 approx. 6.4 W4-E

Splashing water at wall base≥ 3 approx. 3.5 approx. 3.5 approx. 8.5 * To be agreed separately for combination waterproofing in conjunction with water-impermeable concrete floor slabs.

Layer thickness margin according to DIN 18533

du = scratch coat; application rate approx. 0.6 l/m² (dependent on the substrate)dv = - not necessary with layer thickness trowel- without layer thickness trowel, application rate approx. 0.5 l/m² (dmin = 4mm)

-

-

General information

-

Current regulations and legal requirements must be taken into account and deviations from these must be agreed separately.

The relevant test certificates must be observed when planning and carrying out work.

Special agreements and certificates of suitability can be downloaded online at www.remmers.com.

Combination waterproofing in conjunction with water-impermeable concrete slabs must be agreed separately.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-