Article No. 021120

Universal fixing adhesive and thin-coat plaster in the iQ-Therm 2.0 system

Product specifications

On delivery

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Bonding iQ-Therm 2.0 interior insulation strips to the substrate and to each other (bed joints)

- Substrates suitable for plastering, particularly mineral substrates

- Reinforcement and skim coat in the iQ-Therm system

Properties

- Inhibits mould

- Sulphate-resistant

- Enables water vapour diffusion

- Highly capillary active

- Insusceptible to moisture

- Reliable fixing and prevention against slipping

-

Preparation

-

Substrate requirements

Clean, dust-free and capable of supporting a load.

-

Preparations

Pre-wet absorbent plaster substrates so that they are slightly damp.

-

-

Application

-

Contact layer

Pre-wet absorbent substrates.

If necessary, apply the product as a contact layer using a suitable tool.

Vertical bonding layer

Apply the material vertically over the entire surface with a suitable notched trowel in the appropriate layer thickness so that an adhesive bed is created with a layer thickness of approx. 3 mm. The adhesive bed must be free of cavities.

Horizontal bonding layer

Apply material in slurry consistency using a paintbrush or wide brush on bed joints for subsequent iQ-Therm 2.0 strips, thickness approx. 1 mm.

If necessary, produce the bottom bonding layer with undiluted material in a higher layer thickness to achieve a horizontal iQ-Therm 2.0 base layer.

Reinforcing layer

Apply the material with a notched trowel so that a final layer thickness of at least 3 mm is obtained.

Embed the fabric in the centre of the reinforcement layer while it is still wet.

Ensure that fabric sheets overlap by at least 10 cm.

Surface decoration

Apply the material at least 2 mm onto the sufficiently set reinforcement layer.

Smooth the surface using a suitable tool.

Finish the surface once set.

-

Application instructions

-

Once it has hardened, mortar must not be made workable again by adding either water or more wet mortar.

Depending on the ambient conditions, in heated rooms or draughty areas, use a film or similar apparatus to prevent the material from setting too quickly.

Hairline/shrinkage cracks are safe and are not cause for complaint as they do not impair the properties of the mortar.

An additional intermediate layer of filler must be added in order to achieve the elevated surface quality grade Q3.

-

-

Working tools / cleaning

-

Mixing tool, notched trowel, trowel, smoothing trowel, plasterer's float, sponge float

Clean tools with water while the material is still fresh.

-

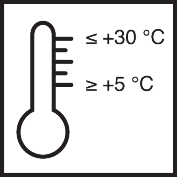

Storage / shelf life

-

If stored in an unopened container and in a dry place, the product will keep for approx. 12 months.

-

Usage

-

Approx. 1.3 kg/m²/mm layer thickness

Approx. 3 mm as adhesive mortar (depending on the evenness of the substrate)

Approx. 1 mm as slurry in the bed joints

At least 5 mm as reinforcement and thin-coat plaster

-

General information

-

Do not work on substrates where moisture is penetrating from the rear.

The colour that is obtained after drying and hardening depends on the ambient conditions and the processing method. For instance, a freshly smoothed surface will be lighter than one that is smoothed later or roughened. Different grain sizes of the same product may lead to slight differences in colour. Substrates soaked from the back may cause discolouration.

May contain traces of pyrite (iron sulphide).

The mixing water must be of drinking water quality.

Low chromate content in accordance with Directive 2003/53/EC.

Always set up a trial area/trial areas first.

Current regulations and legal requirements must be taken into account and deviations from these must be agreed separately.

The relevant test certificates must be observed when planning and carrying out work.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-