Article No. 294025

Two-component, multi-functional building waterproofing material based on renewable raw materials

Product specifications

On delivery

Approx. 8 hrs for 4 mm layer thickness (23 °C/50% RH)

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Rapid waterproofing

- Waterproofing in new buildings

- Can be applied > 3 m in the ground

- Mineral substrates

- Exterior waterproofing in strip form for construction joints on concrete components with high resistance to pressing water penetration (water impact class W2.1-E)

- Waterproofing of new buildings according to DIN 18533 for water impact classes W1-E, W2.1-E, W3-E and W4-E

- Waterproofing of plinths and base points

- Bonding layer on old bitumen coatings

Properties

- Very low emissions (GEV-EMICODE EC 1Plus)

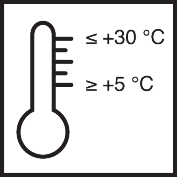

- Fast drying and cross-linking after 24 hours at 5 °C and 90% relative humidity

- Solvent-free

- Bitumen-free

- Water pressure tight

- Radon-tight (verified through testing)

- High tensile adhesion strength

- Highly flexible, elastic and crack-bridging

- Can be plastered and painted over

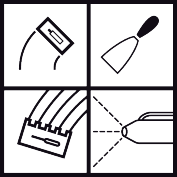

- Can be applied as a slurry, with a brush or trowel, or by spraying

- Excellent adhesion even on non-mineral substrates (e.g. plastics, metals)

- UV-resistant

-

Preparation

-

Substrate requirements

The substrate must be clean, dry, flat and capable of bearing a load, and free of dust, oil, grease and release agents.

Roughen non-mineral and pore-free substrates.

Absorbent mineral substrates may be slightly damp.

-

Preparations

Remove projecting seams and mortar remains.

Break off or chamfer corners and edges.

Reinforce inner corners and connection areas to non-mineral building components with Tape VF. Alternative for internal corners: create a mineral sealing cove using a suitable mortar, e.g. WP DKS rapid (basic).

Seal construction joints of concrete cellars with WP DKS rapid [basic].

Use a suitable mineral mortar or MB 2K [eco] mixed with a suitable quartz sand (1:1 to 1:3 by mass) to seal depressions > 5mm.

Coarse-pored substrates can be sealed beforehand using a scratch coat of MB 2K [eco] mixed with sand (Selectmix RMS).

Openings can be reinforced with a sealing sleeve for pipe feed-throughs, Tape VF 350 HC.

If necessary, provide damp proofing.

Prime absorbent, mineral substrates with Kiesol MB.

Apply a scratch coat of the product as a contact layer and to prevent blistering (approx. 350 - 500 g/m² MB 2K [eco]).

-

-

Preparation

-

Combination container

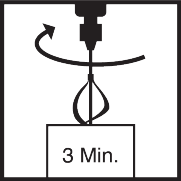

Stir the liquid component with a suitable mixing tool.

Loosen the powder component and add it in full to the liquid component.

Mix for approx. 1 minute before suspending the mixing process to allow the air that has been stirred in to escape.

Remove the powder adhering to the side.

Mix again for approx. 2 minutes.

-

Application

-

Surface waterproofing

Apply the product in two layers on the previously prepared substrate.

Pipes passing through walls

W1-E: seal pipe penetrations by using the product to form a cove around them.

W2.1-E: use an adhesive flange or a suitable loose/fixed flange to integrate pipe penetrations into the waterproofing material.

Connection details/building element joints

Reinforce corner and connection joints as well as connections to rising building components (e.g. floor-to-ceiling windows, doors, etc.) with Tape VF.

Apply the product, embed Tape VF over the entire surface, ensuring that there are no bubbles or creases.

Subsequent coatings

After 4 hours, work can be continued with adhesive mortar, filling

mortar or reinforcement mortar.

-

Application instructions

-

During application, the surface temperature of the substrate must be > 3 kelvin above the dew point temperature of the surrounding air.

In the case of liquid-applied waterproofing materials, direct sunlight and/or wind exposure can cause accelerated skin formation and accompanying blistering.

Do not use in direct sunlight.

Do not use on untreated aluminium.

The scratch layer does not as a rule count as a waterproofing layer.

The maximum total wet film thickness must not exceed 8 mm.

Moving the material (e.g. by stirring) in the mixing bucket can prevent premature skin formation.

Mortar that has already set cannot be made workable again by adding

water or fresh mortar.Protect the fresh waterproofing layer from rain, direct sunlight, frost and condensation water.

Once dry, protect from mechanical damage.

Please contact Remmers Technical Service (phone +49 5432 83900) before applying with machine processing.

Ensure sufficient ventilation when applying the product in closed areas (wear respiratory protection if necessary).

Instructions for spray application:

Personal protective equipment required.

When applying by spraying, wear respiratory protection with particle filter P2 and safety glasses, suitable protective gloves and clothing.

-

-

Working tools / cleaning

-

Mixing tool, scoop, layer thickness trowel

Clean tools with water while the material is still fresh.

Any material that has already begun to dry can only be removed mechanically.

-

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 9 months.

-

Usage

-

Approx. 1.15 kg/m²/mm dry layer thickness

Approx. 4.6 kg/m² for a dry layer thickness of 4 mm -

Apply to a large enough trial area to determine the precise amount required.

-

Application examples

-

Water impact classes

(DIN 18533/18535)

Dry layer thickness

(mm)Wet layer thickness (mm)

Application rate (kg/m²)

Yield 25 kg (m²)

W1-E* Ground moisture and non-pressing water ≥ 3 approx. 3.3 approx. 3.45

approx. 7.2

W2.1-E**

Moderate impact of pressing water ≤ 3 m immersion depth

≥ 4

approx. 4.4

approx. 4.6

approx. 5.4 W2.1-E**

Transition to components made of water-impermeable concrete

Moderate impact of pressing water ≤ 3 m immersion depth

≥ 4

approx. 4.4

approx. 4.6

approx. 5.4

W3-E**

Non-pressing water on earth-covered slabs ≥ 3

approx. 3.3

approx. 3.45

approx. 7.2

W4-E Splashing water and ground moisture at the wall base, and capillary water in and under walls

≥ 2 approx. 2.2

approx. 2.3 approx. 10.9

W2-B

Water load in tanks with a fill level ≤ 10 m

≥ 4 approx. 4.4 approx. 4.6 approx. 5.4

* Special agreement required on masonry** Special agreement requiredLayer thickness margin according to DIN 18533:du = scratch coat application rate approx. 0.5 kg/m² (depending on the substrate)dv = not necessary with layer thickness trowel / application rate without layer thickness trowel approx. 0.4 kg/m² (dmin = 3 mm)

-

-

General information

-

The characteristic data of the product were calculated under laboratory conditions at 20°C and 65% relative humidity.

May corrode metals.

Current regulations and legal requirements must be taken into account and deviations from these must be agreed separately.

Certificates of suitability (abP) must be observed during planning and execution.

Special agreements and certificates of suitability can be downloaded online at www.remmers.com.

Always set up a trial area/trial areas first.

Peel tests are neither suitable nor authorised for assessing the suitability of the product for use.

-

-

Disposal instructions

-

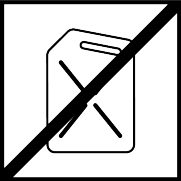

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-

![WP DKS [basic] WP DKS [basic]](https://m.remmers.com/gebindeabbildungen/2400w/81238.png?w=100)

![DS Protect [basic] DS Protect [basic]](https://m.remmers.com/gebindeabbildungen/2400w/81108.png?w=100)