Article No. 043525

Grout for brick pointing

Product specifications

On delivery

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Repair of joints in brick/clinker facades in the facade slurry system

Properties

- Water vapour diffusion capable

- High sulphate resistance and low active alkali content (SR/NA)

- Especially good flank adhesion

- Suitable for narrow joints

- Good resistance to weathering

- Special colours (UV-resistant pigments) available

-

Preparation

-

Substrate requirements

Clean, dust-free and capable of supporting a load.

-

Preparations

Joint depth min. 2 mm, max. 10 mm

-

-

Application

-

Chase out destroyed brick and joints, replace them and level any deep-set joints.

When using for laying bricks and levelling surfaces, mix jointing slurries with Selectmix RMS in a ration of 1:1.

Only mix as much mortar as can be used within approx. 2 hours.

Using a black plasterer's float, apply the slurry over the entire surface area and press into the joints.

Level off sharply and remove excess material.

Use a red or yellow sponge float to compact and level off the slurry.

Without waiting, rub the surfaces with the sponge float attached to the cleaner unit, removing the excess.

Then clean once with clean water, before changing the water and cleaning again.

-

Application instructions

-

The method must be adapted to suit the specific conditions of the project (set up a trial area).

Keep the amount of water used for cleaning to a minimum.

Always use clean water for the final cleaning process.

Wait until at least the next day to clean again using Combi WR.

Waiting time between cleaning and preliminary impregnation: at least 3 rain-free days.

Waiting time between preliminary impregnation and pointing: at least 5 days.

Waiting time between pointing and reimpregnation: at least 8 days.

Once it has hardened, mortar must not be made workable again by adding either water or more wet mortar.

The type and duration of the reworking and surface treatment will influence the colour.

Slight deviations in colour between different batches are possible.

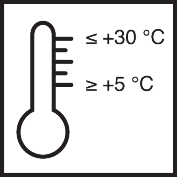

Protect wet mortar surfaces against frost, rain and drying out too quickly for at least 4 days.

-

-

Working tools / cleaning

-

Mixer, trowel, smoothing trowel, foam rubber scraper, sprayer (solvent-resistant design, 404001), mobile cleaner

Clean tools with water while the material is still fresh.

-

Storage / shelf life

-

If stored in an unopened container and in a dry place, the product will keep for approx. 12 months.

-

Usage

-

The brick grout pointing method contains the following system components:

- Pre-impregnation: approx. 0.6 l/m² (Funcosil SNL)

- Grout pointing: approx. 3.0 kg/m²

- Post-impregnation: approx. 0.4 l/m² -

Apply to a large enough trial area to determine the precise amount required.

-

General information

-

Not suitable for grained or sanded brick, hand-moulded bricks or bricks with a textured surface.

May contain traces of pyrite (iron sulphide).

The characteristic data of the product were calculated under laboratory conditions at 20°C and 65% relative humidity.

Do not use on gypsum-based substrates.

Low chromate content in accordance with Directive 2003/53/EC.

The mixing water must be of drinking water quality.

Special colour according to colour number (MF no., colour swatches, NCS etc.) or submitted sample (in the case of changing or alternating colours, clearly mark the desired colour).

The colour that is obtained after drying and hardening depends on the ambient conditions and the processing method. For instance, a freshly smoothed surface will be lighter than one that is smoothed later or roughened. Different grain sizes of the same product may lead to slight differences in colour. Substrates soaked from the back may cause discolouration.

Always set up a trial area/trial areas first.

Current regulations and legal requirements must be taken into account and deviations from these must be agreed separately.

The relevant test certificates must be observed when planning and carrying out work.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-

![Clean AC [basic] Clean AC [basic]](https://m.remmers.com/gebindeabbildungen/2400w/173507.png?w=100)