The mineral waterproofing slurry guarantees reliable and straightforward application every time. Thanks to fast drying times, surfaces are ready for further work after just a few hours.

Article No. 300106

3 in 1 composite waterproofing Combines the functions of waterproofing, tile cement and joint filler in one material

Product specifications

On delivery

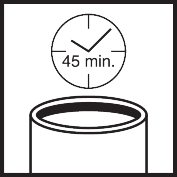

2 mm layer thickness: approx. 8 hours (23°C, 50% RH); approx. 22 hours (5°C, 90% RH)

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

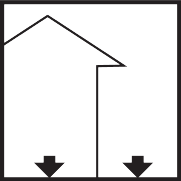

Field of application

- 3 in 1: waterproofing, tile cement and joint mortar

- Interior and exterior, floor areas

- Waterproofing in a bond under tiles (AIV-F) according to DIN 18534-3

- Suitable for new and old buildings

- Waterproofing balconies and covered walkways according to DIN 18531-5

- Waterproofing bathrooms and transition areas in swimming pools

Properties

- Highly flexible

- Water impermeable

- Reactive drying

- A light colour shade enables pigmentable joint colours

- Joint width of 6 - 12 mm

- For heated floor coverings

-

Preparation

-

Substrate requirements

The substrate must be clean, dry, flat and capable of bearing a load, and free of dust, oil, grease and release agents.

Roughen non-mineral and pore-free substrates.

Absorbent mineral substrates, not self-compacting concrete (SCC), may be slightly damp.

-

Preparations

Remove projecting seams and mortar remains.

Break off or chamfer corners and edges.

Prime absorbent mineral substrates with Kiesol MB.

Create a scratch coat using the product as a contact layer and in order to prevent blisters.

If necessary, use suitable products to level out any sloping (e.g. Betofix R4 EM).

Waterproofing:

Reinforce connection areas such as floor-to-ceiling doors and window elements, internal corners, floor-to-wall connections and transitions to balcony edge profiles with joint tape from the Tape VF series.

In interior areas:

Interiors: calcium sulfate screeds must be sanded then vacuumed.

Residual moisture CA/CAF screed heated < 0.3 CM-%/ unheated <0.5 CM-%.

Prime gypsum-based substrates (Primer Hydro F).

-

-

Application

-

Waterproofing:

Apply at least two coats of the product to the prepared substrate in accordance with the regulations.

The total dry layer thickness must be ≥ 2 mm.

Connection details/building element joints

Reinforce internal corners and connection joints, as well as connections to non-mineral building components with joint tape from the Tape VF series.

Apply the product, embed Tape VF over the entire surface, ensuring that there are no bubbles or creases.

Laying the tiles:

Existing waterproofing layers must be completely dry before further work is carried out.

Apply the product as a thin-bed mortar using a suitable notched trowel, and lay the covering material in the fresh mortar bed before a skin forms.

In outdoor areas or when laying large-format tiles and slabs, application using the buttering floating method is recommended.

Immediately remove any soiling / mortar residue on the surface of the covering with water, keep the joint area free of mortar residue.

Grouting tiles:

The joints must be completely dry to avoid trapping moisture in the joint. Apply MB FL 2K grout to the joints with an epoxy grouting scraper in sections. If necessary, the consistency for use as a grout can be adjusted by adding max. 300 ml clean water (to 6.67 kg material). Wipe surfaces promptly with a sponge and wash clean with a sponge float and water. After complete drying, residues/adhesions can be cleaned with Remmers Clean FL.

Adding colour to joints:

The MB FL 2K joint filler can be tinted with pigments from MIXOL® and can be added to the total mass of tinting concentrate up to a maximum of 1.2% as needed and depending on the desired colour.

Colour variants:

Light grey: 60 ml MIXOL® UNIVERSAL TINTING CONCENTRATE No. 25 (oxide white) / 6.67 kg MB FL 2K

Basalt: 10 ml MIXOL® UNIVERSAL TINTING CONCENTRATE No. 29 (oxide brilliant black) / 6.67 kg MB FL 2K

Anthracite: 40 ml MIXOL® UNIVERSAL TINTING CONCENTRATE No. 29 (oxide brilliant black) / 6.67 kg MB FL 2K

Add the required amount of pigment to the liquid component and mix with a suitable mixing tool. Only the two MIXOL® colours mentioned have been tested and approved for adding colour to MB FL 2K.

-

Application instructions

-

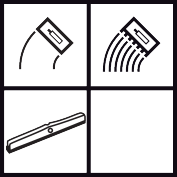

In the case of liquid-applied waterproofing materials, direct sunlight and/or wind exposure can cause accelerated skin formation and accompanying blistering.

Do not use in direct sunlight.

Do not use on untreated aluminium.

The scratch layer does not as a rule count as a waterproofing layer.

The maximum total wet coat thickness must not exceed 5 mm.

Moving the material (e.g. by stirring) in the mixing bucket can prevent premature skin formation.

Mortar that has already set cannot be made workable again by adding

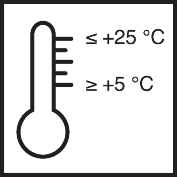

water or fresh mortar.Protect the fresh waterproofing layer from rain, direct sunlight, frost and condensation water.

Once dry, protect from mechanical damage.

Add a further load-distributing layer if using the product for waterproofing under raised floor supports.

Ensure sufficient ventilation when applying the product in closed areas (wear respiratory protection if necessary).

-

-

Working tools / cleaning

-

Clean tools with water while the material is still fresh.

Any material that has already begun to dry can only be removed mechanically.

Dry, adhering material can be cleaned with Remmers Clean FL.

-

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 9 months.

-

Usage

-

As waterproofing:

Min. 1.3 kg/m²/mm dry layer thickness

As tile cement:

8 mm tooth: approx. 2.9 kg/m²

10 mm tooth: approx. 3.5 kg/m²

12 mm tooth: approx. 4.4 kg/m²

As joint filler:

Approx. 0.2 kg/m² (6 mm joint width, tile 30/60 cm, 6 mm thick, total joint length 410 cm)

-

General information

-

The characteristic data of the product were calculated under laboratory conditions at 20°C and 65% relative humidity.

Current regulations and legal requirements must be taken into account and deviations from these must be agreed separately.

Certificates of suitability (EAD) must be observed during planning and execution.

Special agreements and certificates of suitability can be downloaded online at www.remmers.com.

Always set up a trial area/trial areas first.

Peel tests are neither suitable nor authorised for assessing the suitability of the product for use.

Joints in exterior areas: To prevent possible green growth on surfaces grouted with MB FL 2K, it is recommended to add Remmers Protect MKT 1.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-

![Betofix R4 EM [basic] Betofix R4 EM [basic]](https://m.remmers.com/gebindeabbildungen/2400w/38637.png?w=100&version=1)