Article No. 031220

Flowable mineral filler and injection mortar

Product specifications

On delivery

28 d: approx. 1.5 N/mm²

28 d: approx. 3.5 N/mm²

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Strengthening hollow and loose masonry (according to WTA Code of Practice 4-3)

- Filling joints and boreholes

- Preliminary injection of boreholes in multi-stage injection

Properties

- Low viscosity (very good flow properties)

- Low shrinkage

- High sulphate resistance and low active alkali content (SR/NA)

-

Preparation

-

Substrate requirements

Drilling channel must be free of drill dust.

-

Preparations

Strengthening hollow masonry

Creation of drill holes: diameter 18 - 30 mm, angle of inclination approx. 45°, hole depth up to max. 5 cm from end of wall.

Subsequent horizontal waterproofing of masonry

Production of drill holes:

Single row, diameter 18 - 30 mm, distance 10 - 12.5 cm, angle of inclination approx. 45°, drill hole depth up to approx. 5 cm before end of wall.For walls > 0.6 m thick, it is recommended to make the series of drill holes on both sides.

-

-

Application

-

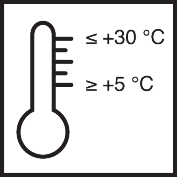

Application requirements

Temperature of material, environment and substrate: min. +5 °C up to max. +30 °C

-

Filling voids

Pressureless, via funnel.

Low pressure filling via suitable injection equipment and injection packers.

Subsequent horizontal barrier - multi-level injection -

Pre-inject/fill hollow masonry via drill holes.

Pierce filled holes with a lance/pin after stiffening.

-

Application instructions

-

Once it has hardened, mortar must not be made workable again by adding either water or more wet mortar.

Protect wet mortar surfaces against frost, rain and drying out too quickly for at least 4 days.

Please contact Remmers Technical Service (phone +49 5432 83900) before applying with machine processing.

-

-

Working tools / cleaning

-

Mixing tools, hopper, injection packers, suitable injection pumps (e.g. Desoi)

-

Clean tools with water while the material is still fresh.

-

Storage / shelf life

-

If stored in an unopened container and in a dry place, the product will keep for approx. 12 months.

-

Usage

-

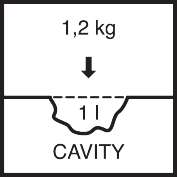

Approx. 1.2 kg/l cavity

-

Apply to a large enough trial area to determine the precise amount required.

-

General information

-

Do not use on gypsum-based substrates.

May contain traces of pyrite (iron sulphide).

The mixing water must be of drinking water quality.

Low chromate content in accordance with Directive 2003/53/EC.

Always set up a trial area/trial areas first.

The characteristic data of the product were calculated under laboratory conditions at 20°C and 65% relative humidity.

Current regulations and legal requirements must be taken into account and deviations from these must be agreed separately.

The relevant test certificates must be observed when planning and carrying out work.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-