Article No. 289106

Polymer-modified joint filler

Product specifications

On delivery

Approx. 5.0 l / 25 kg

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- For interior and exterior use, in dry and wet environments

- Joint widths 4 - 20 mm

- For heated floor coverings

- Grouting ceramic wall and floor coverings

- Glass brick walls

Properties

- Very low emissions (GEV-EMICODE EC 1Plus)

- High abrasion resistance

- Reduced water absorption

- Flexible jointing mortar in accordance with DIN EN 13888

- Resistant to water and frost

- Good flank adhesion

-

Preparation

-

Substrate requirements

Clean, dust-free and capable of supporting a load.

-

Preparations

Clean excess adhesive from joints.

-

-

Application

-

Apply slurry over the entire surface area using a rubber trowel and push into the joints.

Level off sharply and remove excess material.

Use a slightly damp sponge to remove grout residue after it has set.

-

Application instructions

-

Once it has hardened, mortar must not be made workable again by adding either water or more wet mortar.

Do not use on areas directly exposed to sunlight or on heated surfaces.

Touch the material to determine whether it has hardened sufficiently and is ready for washing.

Keep the amount of water used for cleaning to a minimum.

Always use clean water for the final cleaning process.

Protect the material from drying too quickly.

-

-

Working tools / cleaning

-

Mixing tool, rust-proof trowel, plasterer's float, sponge float, sponge

Clean tools with water while the material is still fresh.

-

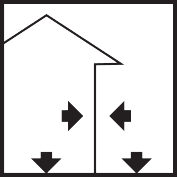

Storage / shelf life

-

If stored in an unopened container and in a dry place, the product will keep for approx. 12 months.

-

Usage

-

Approx. 1.8 kg/m²/mm layer thickness

-

General information

-

Low chromate content in accordance with Directive 2003/53/EC.

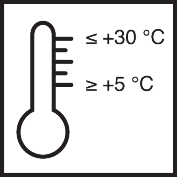

The characteristic data of the product were calculated under laboratory conditions at 20°C and 65% relative humidity.

The mixing water must be of drinking water quality.

May contain traces of pyrite (iron sulphide).

The level of moisture in the substructure and the ambient conditions affect the hardening process and the colour brilliance.

Light colours that are easily affected by dirt should not be used on floors.

Current regulations and legal requirements must be taken into account and deviations from these must be agreed separately.

The relevant test certificates must be observed when planning and carrying out work.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-