Article No. 111325

Crack-bridging, mineral surface protection system (OS 5b, OS DI) with general test certificate according to DIN 18533 / PG-FBB

Product specifications

On delivery

2 mm as OS 5b/OS DI (2 layers)

2 mm as MWS (2 layers)

Wet:

2.3 mm as OS 5b/OS DI (2 layers)

2.3 mm as MWS (2 layers)

R1-E according to DIN 18533-1

R1-B according to DIN 18535-1

W1-B according to DIN 18535-1

BROOF class t1 (DIN EN 13501-5)

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Surface protection system for concrete according to DIN EN 1504-2 for methods 1.3, 2.2, 2.3, 7.7, 8.2 and 8.3

- Meets the requirements of the OS 5b/OS DI system at a layer thickness of 2 mm

- Coating for concrete surfaces that are exposed to weathering and not subjected to wheel loads, with near-surface cracks also in the spray area of de-icing salts

- Waterproofing under permeable road surfaces

- Waterproofing according to DIN 18533

- Waterproofing building element joints according to PG-FBB

Properties

- Freeze/thaw resistant

- Plastic-modified

- Tested on crack formation of greater than 3 mm (according to DIN EN 14891)

- Resilient to cold down to -20 °C (B2)

- Rainproof after 2 hours

- Fire behaviour class B-s1, d0 (DIN EN 13501-1)

- Can be applied by machine

- Radon-tight (verified through testing)

-

Preparation

-

Substrate requirements

The substrate must be clean, dry, flat and capable of bearing a load, and free of dust, oil, grease and release agents.

Roughen non-mineral and pore-free substrates.

Absorbent mineral substrates, not self-compacting concrete (SCC), may be slightly damp.

-

Preparations

Remove projecting seams and mortar remains.

Break off or chamfer corners and edges.

Use a suitable mortar to create a sealing cove.

Seal off indentations > 5 mm using a suitable filling knife.

Roughen the surface of plastic pipes; clean and, if necessary, sand metal pipes.

Apply a scratch coat of the product to act as a contact layer and reduce blistering.

-

-

Preparation

-

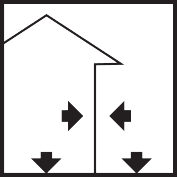

Combination container

Mixing ratio liquid : powder = 1 : 1.87

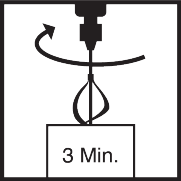

Stir the liquid component with a suitable mixing tool.

Loosen the powder component and add it in full to the liquid component.

Mix for approx. 1 minute before suspending the mixing process to allow the air that has been stirred in to escape.

Remove the powder adhering to the side.

Mix again for approx. 2 minutes.

Keep the mixing tool near the bottom of the bucket while mixing.

-

Application

-

Apply a scratch coat to the sanded substrate. Use a slurry brush, smoothing trowel or spraying equipment to apply in two layers.

Apply the product in two layers on the previously prepared substrate.

Apply second layer once sufficiently dry.

-

Application instructions

-

Once it has hardened, mortar must not be made workable again by adding either water or more wet mortar.

When using liquid waterproofing materials, exposure to direct sunlight and/or wind can accelerate skin formation and cause blistering.

The maximum total wet coat thickness must not exceed 5 mm.

Moving the material (e.g. by stirring) in the mixing bucket can prevent premature skin formation.

Do not use in direct sunlight.

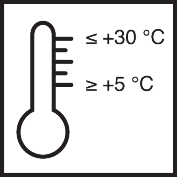

Protect fresh waterproofing from rain, frost and condensation.

Once dry, protect from mechanical damage.

Please contact Remmers Technical Service (phone +49 5432 83900) before applying with machine processing.

-

-

Working tools / cleaning

-

Mixing tool, trowel, wide brush

Clean tools with water while the material is still fresh.

Remove hardened material by tapping or scraping.

-

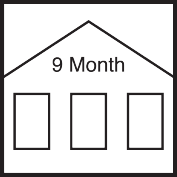

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 9 months.

-

Usage

-

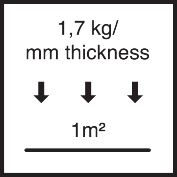

Approx. 1.7 kg/m²/mm dry layer thickness

Approx. 3.4 kg/m² at 2 mm dry layer thickness

-

General information

-

Low chromate content in accordance with Directive 2003/53/EC.

The characteristic data of the product were calculated under laboratory conditions at 20°C and 65% relative humidity.

Current regulations and legal requirements must be taken into account and deviations from these must be agreed separately.

The relevant test certificates must be observed when planning and carrying out work.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not pour liquid coating or residues down the drain, even when cleaning tools used for applying the coating.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-

![WP DKS [basic] WP DKS [basic]](https://m.remmers.com/gebindeabbildungen/2400w/81238.png?w=100)