Article No. 550105

Lightfast 2K finish for highly durable coatings

Product specifications

On delivery

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Interior wood

- Primer & top coat

- Solid wood & veneers

- High-quality furniture and fittings

- Exclusive interior fixtures, kitchen and bathroom furniture

- Handleless front panels

- Tables and worktops

- Topcoat on coloured varnishes (resistance to metal rings, gloss level)

- Coating oak surfaces without green discolouration

Properties

- Good flow properties

- Highly transparent, good emphasis of the wood grain

- Excellent resistance to chemicals

- Good resistance to a wide range of commercially available hand creams

- Resistant to a wide range of PVC plasticisers

- Very high scratch resistance

- Suitable for interior finishing of ships (IMO)

- Lightfast

- Fire resistant

- Gloss level /RM05 & RM10 ResistMat: with reduced tendency to become glossy, good transparency & anti-fingerprint effect

-

Preparation

-

Substrate requirements

The substrate must be clean, dry, free of dust, grease and loose substances, and prepared in the correct manner.

Wood moisture content: 8-12%

-

Preparations

Wash off greasy or resin-rich woods/substrates with WV-891 or V-890. Use UN-894 indoors on the construction site. Ensure good ventilation for solvents.

Sand wood using P 100 - 180 grit.

If colouring is desired, stain the substrate using Aqua KB-004, Aqua BB-007 or Aqua PB-006.

-

-

Application

-

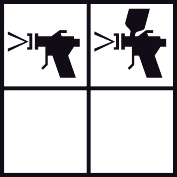

Spray.

Flow cup gun: nozzle size: 2.0 - 2.5 mm; atomiser air pressure: 2.0 - 3.0 bar.

Airless spraying: nozzle size: 0.23 - 0.28 mm, material pressure: 80 - 120 bar.

Airmix spraying: nozzle size: 0.23 - 0.28 mm, material pressure: 80 - 100 bar, atomiser air pressure: 1.2 - 2 bar.

Carry out thorough dull sanding once dry (P 240 - 320).

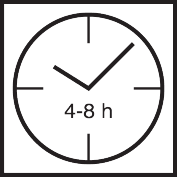

If a second coat is necessary, apply within one working day (4 - 8 hours).

Seal opened containers well and use contents as soon as possible.

Mixed material residues must not be allowed to cure in closed containers.

-

Application instructions

-

Check colour, adhesion and compatibility with the substrate by setting up a trial area.

Before coating technically modified woods and wood-based materials, apply the product to a trial surface and conduct a suitability test on the desired area of use.

Prior to full application, please apply a test coat to a sample area under practical conditions using the desired system, then test or examine the surface properties.

When coating surfaces finished with a coloured varnish, a maximum of 5% of the coloured varnish can be added to the product if necessary. In such cases, it is essential to check the colour.

For optimum durability of the finished surface, a room temperature of at least 20 °C should be maintained during the drying and curing phase (>48 hours).

Substrate-specific coating recommendations can be obtained using the system finder on our website www.remmers.com.

-

Drying

Practice values at +20 °C and 65% relative humidity.

Low temperatures, poor ventilation and high humidity delay drying.

-

Thinning

Ready to use; dilute with max. 10% water if necessary.

-

Working tools / cleaning

-

Airless/airmix spraying equipment, flow cup gun

Clean tools with cold water or Aqua RK-898 Cleaning Concentrate immediately after use.

Ensure that any residue from cleaning is disposed of correctly.

-

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 12 months.

-

Usage

-

80 - 120 ml/m² per coat

-

General information

-

DIN EN 71-3 "Migration of certain elements":

This product complies with the limits for the migration of heavy metals to children's toys according to DIN EN 71-3 and thus fulfils one of several further requirements for the safety of children's toys according to the EU "Toy Directive" (2009/48/EC).Please refer to the relevant test reports/certificates and the Technical Data Sheet for information on certified products and configurations.

For applications in accordance with the Marine Equipment Directive, a maximum wet application rate of 120 ml/m² applies.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not pour liquid coating or residues down the drain, even when cleaning tools used for applying the coating.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-