Article No. 635825

Floor-levelling compound for interior areas

Product specifications

On delivery

Full loading capacity after approx. 28 d

After 7 d: approx. 5 N/mm²

After 28 d: > 7 N/mm²

As per DIN EN 196

After 7 d: approx. 25 N/mm²

After 28 d: > 30 N/mm²

As per DIN EN 196

Vapour-tight coverings/coatings: after approx. 24 h at 3 mm layer thickness

Parquet: after approx. 48 h at 3 mm layer thickness

Otherwise 1 week per 10 mm

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Levelling layer under coatings

- Levelling layer under floor coverings

- Levelling layer under ceramic surfacing

- Layer thickness on cementitious/calcium sulphate based substrates: 3 - 20 mm, in broken-out areas up to 30 mm

- Suitable for use with underfloor heating

Properties

- Hydraulically hardening

- Low-stress

- Treated with synthetic resins

- Good flow properties

- High strength and hardness

- Pumpable

- Very low emissions (GEV-EMICODE EC 1Plus)

- Fire behaviour class A2fl-s1 (as per DIN EN 13501-1)

-

Preparation

-

Substrate requirements

The substrate must be firm, free of cracks and capable of supporting a load. Remove unstable surface coatings and/or separating layers (dirt, dust, oil, paint residues etc.).

-

Preparations

Prime the surfaces with Primer Hydro LC. See the relevant Technical Data Sheet for more information.

Expansion joints, movement joints and edge joints must be retained. Apply strips of insulation material to rising components to prevent the compound from flowing into the connection joints.

Roughen smooth surfaces.

-

-

Application

-

After mixing, pour out the material and spread quickly with a scraper/trowel, then roll with a spiked roller.

Avoid streaks and seams.Going over the surface with a spiked roller improves the surface quality and must be done.

-

Application instructions

-

Once it has hardened, mortar must not be made workable again by adding either water or more wet mortar.

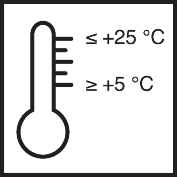

Protect fresh mortar surfaces from frost and ensure that they do not dry out too quickly.

Apply only in single layers.

Please contact Remmers Technical Service (phone +49 5432 83900) before applying with machine processing.

-

-

Working tools / cleaning

-

Mixing tool, bucket for transporting/pouring, scraper, spiked roller

Clean tools with water while the material is still fresh.

Any material that has already begun to dry can only be removed mechanically.

-

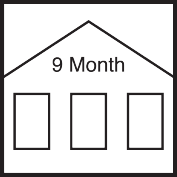

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for 9 months.

-

Usage

-

Approx. 1.6 kg/m²/mm layer thickness

-

Apply to a large enough trial area to determine the precise amount required.

-

General information

-

When using a pore-filling primer with an epoxy resin, it must be ensured that the mixing water can be dissipated via the surrounding air. Longer drying times may need to be taken into account.

The mixing water must be of drinking water quality.

Always set up a trial area/trial areas first.

Low chromate content in accordance with Directive 2003/53/EC.

The characteristic data of the product were determined under laboratory conditions at 20 °C and 50% relative humidity.

The information in TKB publication No. 9 (April 2008) must be observed.

Aesthetic appearance cannot be assured.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-