Article No. 110625

Fibre-reinforced PCC/SPCC (RM/SRM) for static repair of concrete structures / Repair and anode bedding mortar for cathodic corrosion protection

Product specifications

On delivery

7 d = ≥ 40 N/mm²

28 d = ≥ 50 N/mm²

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Concrete replacement for structurally relevant repairs

- Concrete replacement according to

- DIN EN 1504-3 - Repair and anode bedding mortar for cathodic protection

- Wet spraying method

Properties

- High resistance to chloride penetration

- High carbonation resistance

- High resistance to water penetration

- Good water retention capacity, low content of mixing water needed

- Very low shrinkage

- Freeze/thaw-resistant

-

Preparation

-

Substrate requirements

Concrete surface:

Stable, clean, dust-free

Observe the applicable technical regulations for the following parameters:

- Adhesive pull strength of the substrate

- Minimum roughness/roughness depthPre-wet the substrate so that it is slightly moist.

Reinforcement:

Degree of purity SA 2 ½ if applying corrosion protection, otherwise SA 2

-

-

Application

-

Layer thickness

Single layer 5 - 25 mm

Two layers < 50 mm, apply wet on wet

Single layer in broken-out areas < 80 mmThe pre-wet substrate must still be slightly absorbent.

Dilute the product slightly before applying the product to hard-to-reach places in the form of contact sludge.

Apply desired layer thickness and smooth off.

After sufficient drying, felt, rub, smooth or structure the surface.

Subsequent processing

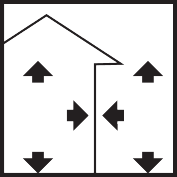

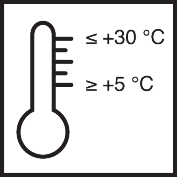

Protect fresh mortar surfaces from wind, direct sunlight, rain and/or frost for at least 3 days so that they do not dry too quickly.

Machine working

Please contact Remmers Technical Service (phone +49 5432 83900) before applying with machine processing.

-

Working tools / cleaning

-

Mixing tool, trowel, smoothing trowel, scraper

Clean tools with water while the material is still fresh.

-

Storage / shelf life

-

If stored in an unopened container and in a dry place, the product will keep for approx. 12 months.

-

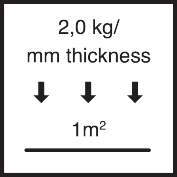

Usage

-

Approx. 2.0 kg/m²/mm layer thickness or 2.0 kg/dm³

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not pour liquid coating or residues down the drain, even when cleaning tools used for applying the coating.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-