Article No. 176405

Water-based, opaque intermediate and final coat for front doors with increased resistance to scratches and hand cream

Product specifications

On delivery

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- For use on interior and exterior wood

- Dimensionally stable wood building elements: front doors

- Intermediate and finishing coats

Properties

- Single component: economical and easy to apply

- Excellent flow properties

- Good resistance to yellowing and chalking

- Weather resistant

- Added bonus of being resistant to scratches and hand cream when surface is subjected to normal use

- Very high resistance to metal rings

- Surfaces do not become shiny

- Resistant and long-lasting thanks to a special polyurethane binding agent

- Highly resistant to temporary water stains

- Compatible with the Induline coating system

-

Preparation

-

Substrate requirements

The substrate must be clean, dry, free of dust, grease and loose substances, and prepared in the correct manner.

Dimensionally stable wood building elements: wood moisture content 11-15%

-

Preparations

If necessary, impregnate non-resistant woods with a wood preservative* (*Use biocides safely. Always read the label and product information before use).

Pre-treat using a suitable primer & intermediate coat and carry out intermediate sanding if necessary.

If necessary, protect parapet joints with Induline V-Joint Protection or Induline AF-920.

-

-

Application

-

Stir well before using.

The values given are based on undiluted material. The best spraying pattern is achieved if the material has a temperature of 15-20 °C.

Airless spraying: nozzle size: 0.28-0.33 mm; material pressure: 90-120 bar.

Air-mix spraying: nozzle size: 0.28-0.33 mm; material pressure: 70-90 bar, atomiser air pressure 1-2 bar.

Seal opened containers well and use contents as soon as possible.

-

Application instructions

-

Check colour, adhesion and compatibility with the substrate by setting up a trial area.

Before coating technically modified woods and wood-based materials, apply the product to a trial surface and conduct a suitability test on the desired area of use.

Prior to full application, please apply a test coat to a sample area under practical conditions using the desired system, then test or examine the surface properties.

Ensure good ventilation.

Do not use in direct sunlight or at temperatures below +15 °C or above +30 °C.

To avoid thicker coats, e.g. in the case of full-tone colours, pretreat with translucent rather than white primer. Then add the coloured topcoat as the intermediate coat.

To prevent coloured substances contained in the wood from showing through, use a suitable primer and intermediate coating with a sealing effect on white or light-coloured surfaces.

With water based coating systems, there is always a residual risk that substances contained in the wood will cause discolouration.

The viscosity of the product may vary considerably depending on the colour selected. These variations are due to the pigment and usually only have a very minor impact on the stability.

For the best spraying results, use a nozzle size of 0.28 mm and pressure of 90 bar.

The system finder on our website www.remmers.com contains coating recommendations for specific wood types to be used when treating windows and exterior doors.

The specifications of VFF Code of Practice HO.03 must be observed with regard to the permitted dry layer thicknesses.

-

Working tools / cleaning

-

Hand spray gun, automatic spraying equipment

Clean tools with water or Aqua RK-898 Cleaning Concentrate immediately after use.

Ensure that any residue from cleaning is disposed of correctly.

-

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 12 months.

-

Usage

-

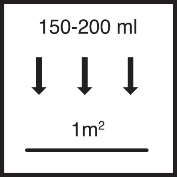

150 - 200 ml/m² (plus spraying loss)

(corresponds to a wet film thickness: 150 - 200 µm, dry film thickness: 55 - 70 µm)

-

General information

-

DIN EN 71-3 "Migration of certain elements":

This product complies with the limits for the migration of heavy metals to children's toys according to DIN EN 71-3 and thus fulfils one of several further requirements for the safety of children's toys according to the EU "Toy Directive" (2009/48/EC).Sealing:

Sealing compounds must be compatible with the coating and may only be applied once the coating has dried thoroughly.

Only use sealing profiles that are free of plasticisers.

Production of corrective lacquers:

In order to repair minor damage to the lacquer (e.g. during installation), mix Induline NW-740/05 with 5% VP 20282 brushable additive (0362).

Care and maintenance:

Wood is subjected to great climatic and environmental stresses when outdoors. The coat is susceptible to the processes of natural ageing, wear and decomposition. Decomposition takes place at different speeds, depending on the stress (weak, average, strong) placed on the wood building element. Weathering stages may vary according to the part or element affected. To give wood the longest and best possible protection it is advisable to examine surfaces every year. Any damage found should be addressed immediately after cleaning.

For cleaning and care, we recommend the care set for doors (2746).

Apply a reconditioning coat of Aqua DL-65 Opaque Top PU.

Observe current standards and guidelines for coating wood building elements outdoors (Codes of Practice issued by the German Association of Window and Facade Manufacturers (VFF), Code of Practice No. 18 issued by the German Federal Committee for Paint and the Protection of Material Assets (BFS), guidelines issued by the German Lacquer and Printing Ink Association (VdL) and ift guidelines issued by the Institut für Fenstertechnik).

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-