Article No. 074312

Silane cream for horizontal barriers against rising damp in masonry

Product specifications

On delivery

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Porous, mineral building materials such as clay brick, sandstone and sand-lime brick

- Subsequent cross-sectional waterproofing of masonry under gravity up to moisture penetration of 95%

Properties

- Inverse formulation for faster action

- Excellent penetration

- Water repellent

- High yielding

-

Preparation

-

Substrate requirements

Drilling channel must be free of drill dust.

-

Preparations

Creating boreholes:

Single row, diameter 12 mm, spacing 12 cm, horizontal plane, borehole depth up to approx. 5 cm from end of wall.For walls > 0.6 m thick, it is recommended to make the series of drill holes on both sides.

-

-

Application

-

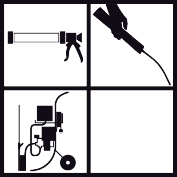

Inject material using suitable injection apparatus depending on the packaging type.

Do not fill the front 2 cm of the boreholes with cream.

-

Application instructions

-

Take appropriate measures to protect adjacent building elements and materials that should not come into contact with the product.

Close drill holes on the same day using WP DS Level (Art. 0426).

Temporary discolouration of the surface may occur in the areas in which the material propagates, in particular on fair-faced masonry.

For the subsequent surface sealing, it is recommended to apply an additional coat of WP DS Level (Art. 0426) in the region of the row of drill holes.

Then, apply surface waterproofing to at least 30 cm above and below the row of drill holes. Include adjacent components if necessary.

We recommend setting up trial areas.

-

-

Working tools / cleaning

-

Desoi PowerPump 70 for 10 l politainer, low-pressure, conveying and spraying equipment with suitable injection lance

-

Clean tools and remove spilled material while it is still wet using Aqua RK-898 Cleaning Concentrate (3868) or Thinner V 101 (0978).

If the machine is to be left unused for longer periods, drain it and clean with RK-898 or Thinner V101.

Ensure that any residue from cleaning is disposed of correctly.

Please contact Remmers Technical Service (phone +49 5432 83900) before applying with machine processing.

-

Storage / shelf life

-

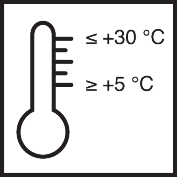

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 12 months.

Use the contents of open containers as quickly as possible.

-

Usage

-

For details see the application rate table under Application examples

-

Application rates will be higher for hollow masonry.

-

Application examples

-

Application rate refers to the borehole volume to be filled, plus a safety margin.Borehole diameter: 12 mmBorehole spacing: 12 cm, i.e. 8.3 holes per m

Wall thickness: Borehole depth: Application rate* per m: 10 cm approx. 8 cm approx. 80 ml 11.5 cm approx. 9.5 cm approx. 100 ml 24 cm approx. 22 cm approx. 230 ml 36 cm approx. 34 cm approx. 350 ml 42 cm approx. 40 cm approx. 415 ml * includes a safety margin of approx. 10%

-

-

General information

-

Not suitable for aerated concrete, gypsum and clay building materials.

Not suitable for new grouting mortar.

A test of effectiveness needs to be carried out on carbonaceous natural stone.

The relevant test certificates must be observed when planning and carrying out work.

The applicable regulations and legal requirements must be observed.

Information on planning injection processes with and processing certified injection materials against capillary moisture transport can be found in WTA Code of Practice 4-10 and must be taken into account.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-