Article No. 559011

Crack-bridging protective coating

Product specifications

On delivery

Component A

Component B

Mixture

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Crack-bridging protective coating for reinforced concrete tanks

- Anti-corrosion coating for steel and galvanised steel

- Coating for liquid manure/silage and biogas facilities, tanks and horizontal silo walls (AbZ Z-59.17-436)

Properties

- With static crack-bridging ability

- Can be subjected to chemical loads

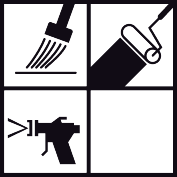

- Application by brush or spraying

- Contains solvents

-

Preparation

-

Substrate requirements

The substrate must be firm, dimensionally stable, capable of bearing loads and free of loose constituents, dust, oil, grease, rubber marks and other substances that could interfere with adhesion.

The adhesive pull strength of the surface after priming must be at least 1.5 N/mm² on average (smallest single value min. 1.0 N/mm²), compressive strength at least 25 N/mm².

For works within the framework of the general building inspectorate approval, the substrates must correspond to the requirements of the approval and the system products mentioned therein must be used.

Concrete max. 4 m% moisture -

Preparations

Prepare the substrate by suitable means, e.g. steel ball jetting or diamond grinding, so that it meets the requirements specified above.

Before coating, close pipes and pores using a stable material, e.g. Epoxy MT 100 with the addition of a standardising agent (Add TX).

Remove rust and rolling skin from steel surfaces e.g. by sandblasting SA 2 1/2.

-

-

Preparation

-

Combination container

Add the entire quantity of the hardener (component B) to the base compound (component A).

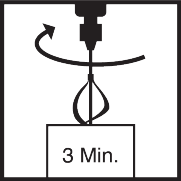

Mix thoroughly with a slow-speed electric mixer

(approx. 300 - 400 rpm).Pour the mixture into a separate container and mix again thoroughly.

Mix for at least 3 minutes.

Insufficient mixing is indicated by streaks forming.

When working with airless spraying equipment (e.g. Storch SL 1100 – piston stroke pump), the prepared mixture can be mixed with up to 20% by mass of Thinner V 103 to achieve the spraying viscosity.

-

Application

-

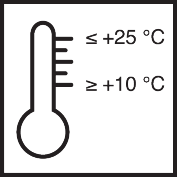

As a general principle, higher temperatures will reduce and lower temperatures will increase the times stated.

-

Working tools / cleaning

-

Epoxy roller, brush, surface brush or airless spraying equipment (e.g. Storch SL 1100 – piston pump), suitable mixing equipment

-

More detailed information can be found in the Remmers Tool Programme.

Clean tools and remove any contamination immediately after use and while fresh using Thinner V 103.

Take suitable protective and waste disposal measures when cleaning.

-

Storage / shelf life

-

If stored unopened in the original container and kept cool, dry and protected from frost, min. 12 months (component A)/min. 24 months (component B).

-

Usage

-

According to authorisation

-

-

Application examples

-

C

Apply the material to the prepared surface and spread evenly using a suitable tool, e.g. epoxy roller, paintbrush, flat brush or airless sprayer (e.g. Storch SL 1100 piston pump).

When applying with an airless sprayer, remove the filters in the intake nozzle and the gun.

When working with airless spraying equipment (e.g. Storch SL 1100 – piston stroke pump), the prepared mixture can be mixed with up to 20% by mass of Thinner V 103 to achieve the spraying viscosity.

(Spray nozzle 527, pressure approx. 190 bar depending on the airless spraye used).

Three-layer application in alternating colours (black/black-red/black) according to test certificate.

1.2 kg/m² binder in three coats

-

-

General information

-

Unless otherwise specified, all of the values and application rates given above have been determined under laboratory conditions (20 °C) using standard colours. Slight deviations from these values may arise if the product is worked with on site.

Not suitable for frequent or constant thermal loads > 60 °C.

The maximum application quantity of 0.40 kg/m² per coat must not be exceeded, otherwise the adhesion of intermediate layers may be affected.

In case of repairs on the surface or working up to existing surfaces, there will be a visible transition in appearance and texture.

Highly abrasive loads lead to increased wear.

Suitable for vehicle traffic with rubber tyres; not suitable for vehicle loads with metal or polyamide tyres nor for dynamic point loads.

Epoxy resins are generally not colourfast when exposed to UV light or weather.

Further notes on working, system construction and maintenance of the listed products can be found in the latest Technical Data Sheets and the Remmers system recommendations.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For professional users only!

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet and the brochure entitled "Epoxy Resins in the Construction Industry and the Environment", issued by Deutsche Bauchemie e.V. (3rd edition 2022).

-