Article No. 717001

Solvent-based all-in-one coating system with sealing action for high-grade timber constructions

Product specifications

On delivery

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- For use on exterior wood

- Dimensionally stable wood building elements: e.g. windows and doors

- Wood building elements with limited dimensional stability, e.g. folding shutters, matchboarding, summerhouses

- Wood building elements with no dimensional stability: e.g. fences, framework, carports, planking

- Primer, intermediate and finishing coats

- Biocide-free finishing coat for impregnated wood, e.g. garden furniture

- Can also be used as a maintenance coat

Properties

- High total solids level for greater covering capacity

- Block resistant (in accordance with Code of Practice HO.03)

- Ventilating effect

- Free of aromatic compounds according to VDL guideline 01

- Easy to apply

- Good edge coverage

- Weatherproof and moisture-regulating

- Isolating effect against substances contained in the wood

-

Preparation

-

Substrate requirements

Dimensionally stable wood building elements: wood moisture content 11-15%

Wood building elements with limited or no dimensional stability: wood moisture content max. 18%

The substrate must be clean, dust-free and dry.

-

Preparations

Thoroughly remove any dirt, grease and non-adhering old coatings.

Thoroughly sand any old coatings that are still intact.

Sand grey and weathered wood surfaces down to sound, bright wood.

Remove any loose and torn knots as well as resin that bleeds from the wood and clean with a suitable product (e.g. V 101 Thinner).

Observe BFS Code of Practice No. 18 "Coatings on Wood and Wooden Working Materials in Outdoor Areas".

Exterior wood that is to be protected against rot and blue stain and/or wood-destroying insects should be pre-treated with a suitable wood preservative* [see system products]. (*Use biocides safely. Always read the label and product information before use.)

-

-

Application

-

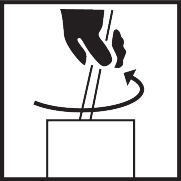

Stir well.

Apply with a brush, roller or by spraying.

Flow cup gun: nozzle size: 2.0 - 2.5 mm; atomiser air pressure: 2.0 - 3.0 bar.

Airless spraying: nozzle size: 0.28-0.33 mm; material pressure: approx. 200 bar.

Air-mix spraying: nozzle size: 0.28-0.33 mm; material pressure: 70-90 bar, atomiser air pressure 1-2 bar.

Apply further coats once dry.

Seal opened containers well and use contents as soon as possible.

-

Application instructions

-

Check colour, adhesion and compatibility with the substrate by setting up a trial area.

Before coating technically modified woods and wood-based materials, apply the product to a trial surface and conduct a suitability test on the desired area of use.

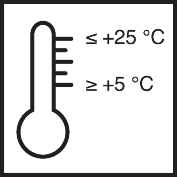

Do not use at temperatures below +5°C.

If the temperature is too low or the humidity too high, it will take longer for the material to reach the desired properties.

When using the product in the workshop or in enclosed spaces, make sure that the area has adequate air circulation and a good supply of fresh air.

Areas that are being coated or dried should be protected against rain, wind, sunlight and condensation.

On surfaces that are not exposed to daylight, e.g. the inner surfaces of windows and external doors, alkyd resin systems exhibit a certain degree of dark yellowing, in particular in rebates.

Bright, intense colours such as yellow, orange and red may have a lower covering capacity as a natural consequence of the pigments used. When using these colours, it is therefore recommended either to first apply a coat of a similar colour with a greater covering capacity, or to apply a second coat in the desired colour.

-

Drying

Dust-dry: approx. 4 hours

Touch-dry: approx. 6-8 hours

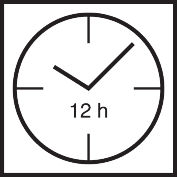

Overcoating: approx. 12 hoursPractice values at +20 °C and 65% relative humidity.

The coating may take significantly longer to dry thoroughly in lower temperatures, at high humidity or if the maximum layer thickness has been exceeded.

Longer drying times can improve the sealing effect.

-

Thinning

Ready to use

Dilute with up to 5% V 101 Thinner if necessary.

-

Working tools / cleaning

-

Brush with natural bristles, mohair roller, foam roller, airless/airmix spraying equipment

-

Clean tools immediately after use with V 101 Thinner.

Ensure that any residue from cleaning is disposed of correctly.

-

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 24 months.

-

Usage

-

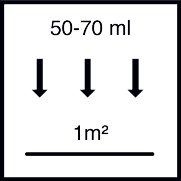

Approx. 50 - 70 ml/m² per coat

-

General information

-

DIN EN 71-3 "Migration of certain elements":

This product complies with the limits for the migration of heavy metals to children's toys according to DIN EN 71-3 and thus fulfils one of several further requirements for the safety of children's toys according to the EU "Toy Directive" (2009/48/EC).The final degree of gloss only sets in approx. 2-3 weeks after application. There may be slight differences in the gloss level depending on the colour.

On planed larch and softwoods with a high resin content, the coating may have reduced adhesion and resistance to weathering. This is especially the case on horizontal year rings, knots and areas of winter growth that are high in resin. Maintenance must be carried out more frequently on these surfaces.

The only remedy for this is pre-weathering or very coarse sanding (P80).

If these wood types are rough-sawn, considerably longer maintenance intervals are to be expected.Observe the regulations concerning design principles for wood protection.

Do not use on horizontal surfaces without drainage slopes and without edge radius, avoid accumulated moisture.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-