Article No. 774103

Durable, cloth matt, texture-preserving opaque coating with sealing properties, made from renewable raw materials, for interior and exterior wood in sensitive areas

Product specifications

On delivery

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- For use on interior and exterior wood

- Dimensionally stable wood building elements: e.g. windows and doors

- Wood building elements with limited dimensional stability, e.g. folding shutters, matchboarding, summerhouses

- Wood building elements with no dimensional stability: e.g. fences, framework, carports, planking

- Primer, intermediate and finishing coats

- Wooden beehives, bee boxes and other wooden elements used in beekeeping

- Playground equipment

- Sustainable building suitable for building certifications DGnB, LEED, BNB, QNG etc.

Properties

- Water-based with a very low solvent content

- Block resistant (in accordance with Code of Practice HO.03)

- Non-drip

- Refined cloth-matt surfaces

- Good flow properties

- Elastic

- Does not flake

- Weather-resistant and UV-resistant

- Less discolouration due to water-soluble substances in the wood

- Based on renewable raw materials

- Bee-friendly formula

-

Preparation

-

Substrate requirements

The substrate must be clean, dry, free of dust, grease and loose substances, and prepared in the correct manner.

Dimensionally stable wood building elements: wood moisture content 11-15%

Wood building elements with limited or no dimensional stability: wood moisture content max. 18%

-

Preparations

Thoroughly remove any dirt, grease and non-adhering old coatings.

Sand grey and weathered wood surfaces down to sound, bright wood.

Remove any loose and torn knots as well as resin that bleeds from the wood and clean with a suitable product (e.g. V 101 Thinner, a nitrocellulose or universal thinner).

In order to avoid the use of wood preservatives as far as possible, the construction should be designed to be water-repellent (avoid horizontal surfaces, open end-grain wood, capillary joints, water and moisture accumulation points, contact with splash water, sharp edges). Pre-treatment with Wood Impregnation [eco] improves the hydrophobic effect.

Exterior wood that needs to be protected against soft rot and blue stain must be pre-treated with a suitable wood preservative* - not necessary for interior wood (*Use biocides safely. Always read the label and product information before use).

With water based coating systems, there is always a residual risk that substances contained in the wood will cause discolouration.

To avoid bleeding of substances in the wood into adjoining building elements (e.g. infilling in framework areas), treat the wood all round.

Old weathered carbolineum coatings can only be coated with dark colours. Always test first with a trial coating.

Observe BFS Code of Practice No. 18 "Coatings on Wood and Wooden Working Materials in Outdoor Areas".

-

-

Application

-

Stir well.

Apply with a brush, roller or by spraying.

Flow cup gun: nozzle size: 2.0 - 2.5 mm; atomiser air pressure: 2.0 - 3.0 bar.

Air-mix spraying: nozzle size: 0.28-0.33 mm; material pressure: 70-90 bar, atomiser air pressure 1-2 bar.

Airless spraying: nozzle size: 0.28-0.33 mm; material pressure: 70-90 bar.

Apply a second coat once the first has dried.

Apply a further coat if required.

Protect end-grain surfaces against water ingress by applying multiple coats of the material in the corresponding colour. Alternatively, coat the end-grain surfaces with Induline SW-910 before applying the final coat.

Seal opened containers well and use contents as soon as possible.

-

Application instructions

-

Check colour, adhesion and compatibility with the substrate by setting up a trial area.

Before coating technically modified woods and wood-based materials, apply the product to a trial surface and conduct a suitability test on the desired area of use.

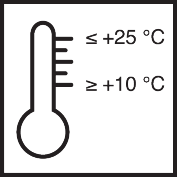

Do not use below +5 °C

If the temperature is too low or the humidity too high, it will take longer for the material to reach the desired properties.

Do not use on wood impregnated with boron salts.

Ensure sufficient ventilation when applying indoors.

Areas that are being coated or dried should be protected against rain, wind, sunlight and condensation.

The colour shown on the sample does not appear until the material has dried.

*Information about self-ignition

In external tests, the tested product exhibited significantly lower reactivity than conventional reference products that dry by oxidation. The risk of self-ignition is therefore classified as lower.

It should be noted that the tests carried out by EPH could not take into account all possible scenarios that might occur in practice. For example, contact of objects and media contaminated with this product, such as rags or dust, with other highly flammable agents, such as dust containing cellulose nitrate or certain solvents, could lead to conditions that result in ignition.

Avoid excessive overspray.

Leave fresh spray mist to dry for at least 48 hours before sweeping up.

Collect spray mist in fireproof waste containers and spray regularly with water to prevent self-ignition of the spray mist, especially if large quantities accumulate.

-

Drying

Dust-dry: after approx. 1 hour

Overcoating: after approx. 6 hoursPractice values at +20 °C and 65% relative humidity.

Low temperatures and high humidity delay drying.

Drying may take longer depending on the type of wood, e.g. oak, due to substances it contains.

-

Thinning

Ready to use

-

Working tools / cleaning

-

Paintbrush with synthetic bristles, flat brush, short-pile roller (5 mm), flow cup gun, airless/airmix spraying equipment

Clean tools with water or Aqua RK-898 Cleaning Concentrate immediately after use.

Ensure that any residue from cleaning is disposed of correctly.

-

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 24 months.

-

Usage

-

Approx. 80 - 100 ml/m² per coat

White and light colours: 3 coats

Medium and dark colours: 2 coats

-

General information

-

DIN EN 71-3 "Migration of certain elements":

This product complies with the limits for the migration of heavy metals to children's toys according to DIN EN 71-3 and thus fulfils one of several further requirements for the safety of children's toys according to the EU "Toy Directive" (2009/48/EC).Bright (especially white), solvent-based and water-dilutable oil and alkyd resin paints will exhibit varying levels of yellowing during their useful life.

Brilliant, pure, intensive colours have a lower hiding power due to their pigments. We recommend fully pre-coating such areas with a matching coloured primer if using critical colours.

When using a transparent protective coating (e.g. in order to make the surface more mechanically resistant or to prevent pigment abrasion), slight changes in the colour may occur.

On planed larch and softwoods with a high resin content, the coating may have reduced adhesion and resistance to weathering. This is especially the case on horizontal year rings, knots and areas of winter growth that are high in resin. Maintenance must be carried out more frequently on these surfaces.

The only remedy for this is pre-weathering or very coarse sanding (P80).

If these wood types are rough-sawn, considerably longer maintenance intervals are to be expected.Observe the regulations concerning design principles for wood protection.

Do not use on horizontal surfaces without drainage slopes and without edge radius, avoid accumulated moisture.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-

![Aqua OWF-68/tm [eco] Aqua OWF-68/tm [eco]](https://m.remmers.com/gebindeabbildungen/2400w/51831.png?w=100&version=5)