Article No. 215725

Water-based, transparent fireproof coating that forms an insulating layer

Product specifications

On delivery

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Interior wood

- Solid wood panels: density ≥ 420 kg/m³, thickness ≥ 10 mm

- Wood-based panels: density ≥ 600 kg/m³, thickness ≥ 13 mm

- Veneered plywood for construction purposes according to the norm DIN EN 13986 with a fire behaviour of at least class D-s2,d0, with a bulk density of ≥ 450 kg/m³ and a thickness of ≥ 12 mm

- Roof structures, wall and ceiling cladding

- Schools, restaurants, hospitals, residential and office buildings

Properties

- Slows down the spread of fire and reduces the smoke development as well as the flammability of the substrate

- A heat-insulating layer is formed in the event of a fire

- Water-based

-

Preparation

-

Substrate requirements

The substrate must be clean, dry, free of dust, grease and loose substances, and prepared in the correct manner.

Wood moisture content max. 15%

-

Preparations

Fully remove any existing old coatings.

Thoroughly wash down resin-rich and oily woods with V 101 Thinner immediately before coating.

In the event of wetting difficulties, rub the surface down thoroughly.

-

-

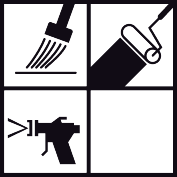

Application

-

Application requirements

Temperature of the material, air and substrate: from min. +10 °C to max. +30 °C.

-

Stir well.

Apply with a brush, roller or by spraying.

Airless spraying: nozzle size: 0.33 mm, material pressure: 80 - 100 bar.

Airmix spraying: nozzle size: 0.33 mm, material pressure: 80 - 100 bar, atomiser air pressure: 1.5 - 2.0 bar

Repeat the process if necessary.

Seal opened containers well and use contents as soon as possible.

-

Application instructions

-

Check colour, adhesion and compatibility with the substrate by setting up a trial area.

Wood components must be coated on all sides if they are not affixed over their entire surface to a solid, mineral substrate.

-

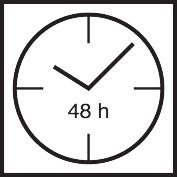

Drying

Dust-dry: after approx. 2 hours

Fully dry: after approx. 24 hours

Overcoating: after approx. 6 hours with Intumescent Coat, after approx. 48 hours with Protective SealerPractice values at +20 °C and 65% relative humidity.

Low temperatures, poor ventilation and high humidity delay drying.

-

Thinning

Ready to use

-

Working tools / cleaning

-

Medium-pile lambswool roller, solvent-resistant flat brush

Airless/airmix spraying equipment:

High-performance piston pump, ratio ≥ 30:1

Remove sieves and filters

Hose diameter ≥ NW 10

Whip 1.5-2 m, NW 6, possible

Use solvent-resistant hoses -

Clean the tools with hot water immediately after use.

Ensure that any residue from cleaning is disposed of correctly.

-

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 18 months.

-

Usage

-

≥ 300 g/m² on solid wood, solid wood boards, veneered laminated wood and flat pressed chipboard (d ≥ 12 mm each)

≥ 350 g/m² on solid wood and solid wood boards (d ≥ 10 mm up to < 12 mm each)

(one to two coats)

-

-

General information

-

Do not stack treated components.

The treated components must be protected against rain and moisture (enclosed spaces, covered structures etc.) and must not be exposed to weathering.

Top coat of Protective Sealer:

To protect the surface against contamination during transportation, adhesive bonding and short-term moisture.

Levels out uneven degrees of gloss.Please note the provisions of the General Building Inspectorate Approval.

The Intumescent Coat always has to be used in combination with the Protective Sealer.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-