Article No. 085517

Lightweight, bitumen-free reactive insulation panel adhesive

Product specifications

On delivery

Approx. 9 hrs (23 °C, 50% RH)

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Bonding perimeter and wall base insulation panels on mineral substrates and existing waterproofing layers

- Bonding insulation panels together

Properties

- High yield thanks to formation of air pores during stirring

- Excellent adhesion

- Safe and fast reaction behind insulating panels

- Ready for filling after a short time, even in unfavourable climate conditions

- High stability

- Lightweight and versatile

- Long-lasting

- Free from bitumen and solvents

-

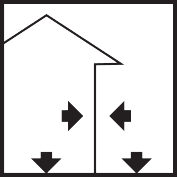

Preparation

-

Substrate requirements

Clean, dry, stable, level and dust-free

Waterproofing layers must be completely dry.

-

-

Preparation

-

Combination container

We recommend a twin stirring unit for mixing.

Depending on the mixing technique used (stirring unit, stirring rod), the application rate may increase/the yield may decrease.The densities and volumes, and the resulting application rates, were determined in practice and in the laboratory under optimal conditions. In addition to the stirrer used and the mixing time, the movement of the mixers in the mixing container (the more frequently and longer the mixing head protrudes from the mixture, the higher the air intake) and the climate conditions also influence the achievable density and yield.

Pour all of the liquid component into the mixing bucket.

Loosen the powder component and add it in full to the liquid component.

Mix for approx. 30 seconds, scrape off any powder adhering to the edge.

Continue mixing for at least 2.5 minutes.

-

Application

-

Apply the adhesive to the entire surface of the insulation panels, including the ends, by buttering and/or floating.

-

Application instructions

-

At high temperatures, the open time can be extended by adding up to 2% VZ MB (3005).

When using liquid-applied, two-component adhesives, direct sunlight and/or wind exposure can lead to accelerated skin formation and associated blistering.

Insulation boards must be firmly fixed at the base point (e.g. projecting foundation) and laid in a bond without joints.

Until the foundation pit has been filled in, secure the insulation boards so that they cannot slip or slide.

Protect freshly bonded panels from rear moisture penetration.

To avoid thermal stresses, the excavation pit must be backfilled promptly.

In the base area, the base insulation boards must be additionally secured above the ground, see also the processing instructions of the base insulation board manufacturer.

Water may be added up to a maximum of 500 ml per container (not in combination with VZ MB).

-

-

Working tools / cleaning

-

Twin stirring unit, ladle, notched trowel 10 mm

Clean tools with water immediately after use

Remove dried material using Aqua RK-898 Cleaning Concentrate.

-

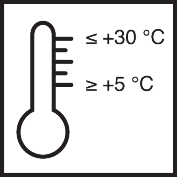

Storage / shelf life

-

If stored in unopened original container in a cool, dry place, protected from frost, the product will keep for at least 9 months.

-

Usage

-

Depending on the substrate condition and density achieved

Approx. 3 - 4 kg/m² for full-surface coverage, applied by buttering/floating

Approx. 1.5 - 2 kg/m² for full-surface coverage, applied by buttering or floating

An additional quantity of the product is needed to bond panel joints, depending on the thickness of the insulation panels.

-

General information

-

The characteristic data of the product were calculated under laboratory conditions at 20°C and 65% relative humidity.

Adding water increases the drying time.

Deviations from current regulations must be agreed separately.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-