Article No. 776005

Water-based, silk gloss two-component epoxy coating

Product specifications

On delivery

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Storage rooms

- Basements and hobby rooms

- Garages

- Workshops

Properties

- Water vapour diffusion capable

- Water-dilutable

- Good adhesion and opacity

- Easy to clean

- High abrasion resistance

- Resistant to fuel and engine oil

- Mix with anti-slip additives for a non-slip finish

- Decorate surface design with scattered flakes

-

Preparation

-

Substrate requirements

The substrate must be prepared with 2K epoxy primer.

-

-

Preparation

-

Combination container

The two components (A and B) are supplied in coordinated containers. Add component B to component A. Ensure that the hardener container (component B) is emptied completely.

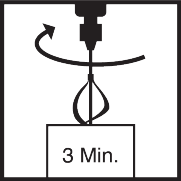

Then mix intensively with a suitable mixer and mixing paddle until no more streaks are visible. A minimum mixing time of 2-3 minutes must be observed. Pour the premixed material into an additional container (e.g. clean paint bucket) and mix again briefly.

To make the sealing system slip-resistant, add the product Anti-Slip Additive in a ratio of 2.5% and mix in thoroughly. This corresponds to adding 125 g (half a container) to a 5 kg 2K floor coating or 2K epoxy primer.

-

Application

-

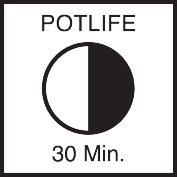

The times given are reduced at higher temperatures and increased at lower temperatures, in particular in combination with high humidity.

-

Working tools / cleaning

-

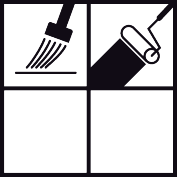

10 cm and 25 cm epoxy roller, brush, suitable mixing equipment

-

More detailed information can be found in the Remmers Tool Programme.

Clean tools, equipment and any splashed material immediately with water while still fresh.

Take suitable protective and waste disposal measures when cleaning.

-

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 12 months.

-

Usage

-

Approx. 0.15 - 0.25 kg/m²

-

-

Application examples

-

S

Evenly apply the prepared mixture e.g. using the Remmers epoxy roller (25 cm) and re-roll crosswise. It is recommended to use a paint grid for even application. Do not allow the material to pool. Along rising components, in difficult-to-reach areas and corners, apply the material using a suitable flat brush and a 10 cm epoxy roller.

Coloured sealant:

approx. 0.15-0.25 kg/m² 2K floor coating

Non-slip sealant:

approx. 0.15-0.25 kg/m² 2K floor coating plus 2.5% anti-slip additive

Coloured sealant with decorative surface finish:

approx. 0.15-0.25 kg/m² 2K floor coating.

-

-

General information

-

When coating continuous surfaces, only use materials with the same batch number as slight differences in colour, gloss and texture may occur.

When repairing surfaces or working up to existing surfaces, there will be a visible transition in appearance, texture and degree of gloss.

The sealant has a slightly textured surface typical for this type of system.

In order to achieve even surfaces, appropriate allowances for roughness depth must be taken into consideration.

Abrasive mechanical loads leave traces of wear.

Suitable for vehicle traffic with rubber tyres; not suitable for vehicle loads with metal or polyamide tyres nor for dynamic point loads.

Epoxy resins are generally not colourfast when exposed to UV light or weather.

Read the application instructions before use. Recommended for professional users.

Upon prolonged contact with a floor covering, coloured – and especially black – rubber can cause discolouration that cannot be removed (e.g. car tyres or machine bases). Suitable polyurethane wheels or underlay mats should be used in order to avoid such discolouration. Colourants, hair dyes, bleach and disinfectants can also cause discolouration if not removed immediately.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet and the brochure entitled "Epoxy Resins in the Construction Industry and the Environment", issued by Deutsche Bauchemie e.V. (3rd edition 2022).

-