Article No. 363104

Top 2K M Plus

Transparent, slip-resistant, silk-matt sealant

Product specifications

On delivery

Component A

Component B

Mixture

Once fully cured

Once fully cured

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Slip-resistant sealing of EP and PU coatings in areas subject to low mechanical loads

Properties

- Silk matt

- Slip-resistant

- Lightfast

- Water vapour diffusion capable

-

Preparation

-

Substrate requirements

The substrate must be firm, dimensionally stable, capable of bearing loads and free of loose constituents, dust, oil, grease, rubber marks and other substances that could interfere with adhesion.

The substrate must be prepared using suitable Remmers products.

-

Preparations

Apply the sealant within 48 hours. In the case of longer waiting times, sand the surface treated in the previous coat and remove dust.

-

-

Preparation

-

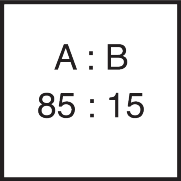

Combination container

Add the entire quantity of the hardener (component B) to the base compound (component A).

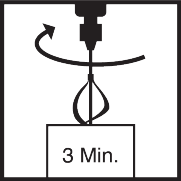

Mix thoroughly with a slow-speed electric mixer

(approx. 300 - 400 rpm).Pour the mixture into a separate container and mix again thoroughly.

Mix for at least 3 minutes.

Insufficient mixing is indicated by streaks forming.

-

Application

-

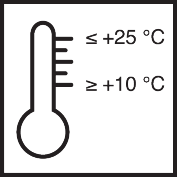

The times given are reduced at higher temperatures and increased at lower temperatures, in particular in combination with high humidity.

-

Working tools / cleaning

-

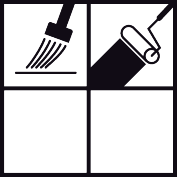

25 cm epoxy roller, 50 cm epoxy roller, mixer

-

The stirrer should be sheathed in plastic (e.g. Remmers patent disperser).

More detailed information can be found in the Remmers Tool Programme.

Clean tools, equipment and any splashed material immediately with water while still fresh.

Take suitable protective and waste disposal measures when cleaning.

-

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 6 months.

-

Usage

-

Approx. 0.13 kg/m²

-

-

Application examples

-

S

Apply the material generously to the surface. Apply the material evenly with a suitable 25 cm epoxy roller in a crosswise motion and then roll on with a 50 cm epoxy roller saturated with material.

approx. 0.13 kg/m² binder

-

-

General information

-

Unless otherwise specified, all of the values and application rates given above have been determined under laboratory conditions (20 °C). Slight deviations from these values may arise if the product is worked with on site.

Use sufficiently experienced personnel to ensure that surfaces are as even as possible.

Uneven application, strong draughts and large temperature differences on the surface can result in a non-uniform surface appearance due to differences in the degree of gloss.

Suitable for vehicle traffic with rubber tyres; not suitable for vehicle loads with metal or polyamide tyres nor for dynamic point loads.

Upon prolonged contact with a floor covering, coloured – and especially black – rubber can cause discolouration that cannot be removed (e.g. car tyres or machine bases). Suitable polyurethane wheels or underlay mats should be used in order to avoid such discolouration. Colourants, hair dyes, bleach and disinfectants can also cause discolouration if not removed immediately.

Maintenance measures are recommended in order to reduce the tendency to soil (see maintenance instructions).

Anti-slip floors naturally require more cleaning effort than smooth surfaces. Therefore, the use of cleaning machines with soft brushes is recommended.

Further notes on working, system construction and maintenance of the listed products can be found in the latest Technical Data Sheets and the Remmers system recommendations.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For professional users only!

Further information concerning safety during transport, storage and handling as well as on disposal and ecology can be found in the latest Safety Data Sheet.

-