Article No. 071505

Elasticised stone strengthener on a silicic acid ester (KSE) base with a high gel deposition rate for strengthening heavily deteriorated mineral building materials

Product specifications

On delivery

Following application

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Strengthening highly porous and heavily weathered joints

- Large-pored sandstone, certain types of volcanic rock and weathered brick, heritage rendering and joints

- Obtaining especially uniform strength profiles when used in combination with KSE 100 and/or KSE 300 E

Properties

- Contains soft segments for a more flexible silica gel

- Good stress-strain behaviour thanks to larger, low-stress silica gel bridges

- Gel deposition rate: approx. 50%

- Non-hydrophobising

- High penetration depth

-

Preparation

-

Substrate requirements

The substrate must be clean, dust-free and dry.

-

Preparations

Any construction defects such as cracks, cracked joints, defective connections, rising damp and hygroscopic moisture must be remedied in advance.

Perform any necessary cleaning gently, e.g. by spraying with cold or warm water or by steam-cleaning; use soft whirl jet technology or Remmers cleaning products (e.g. Traffic Film Remover (0671), Clean FP (0666), Clean AC (0672), Combi WR (0675)) on tough stains.

To avoid material loss of the substrate, an initial strengthening with KSE 100 or an other suitable strengthener can be carried out before any cleaning measure.

-

-

Application

-

Application requirements

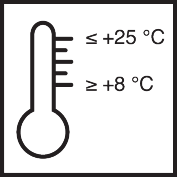

Temperature of the material, air and substrate: from min. +8 °C to max. +25 °C

-

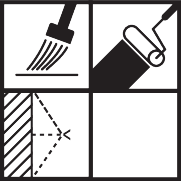

Apply the primer abundantly by flow coating without pressure (avoid misting), so that a 30 - 50 cm long liquid film flows down the surface.

Apply horizontally on one section at a time, moving from top to bottom, and immediately go over with a wide brush.

Repeat the application several (at least two) times (wet on damp) until no further material is absorbed by the substrate.On surfaces where spray application is not possible, apply using a well-saturated brush.

-

Application instructions

-

Take appropriate measures to protect adjacent building elements and materials that should not come into contact with the product.

Remove any excess impregnation agent within 1 hour using V 101 thinner.

Protect freshly treated surfaces from driving rain, wind, sunlight and condensation.

-

-

Working tools / cleaning

-

Solvent-resistant, low-pressure, conveying and spraying equipment, liquid pumps, paintbrush, surface brush and lamb's wool roller

-

Tools must be clean and dry.

After use and before prolonged interruptions of work clean tools with Thinner V 101.

Ensure that any residue from cleaning is disposed of correctly.

-

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 12 months.

Use the contents of open containers as quickly as possible.

After every use, close containers so that they are air-tight, since silica gel reacts with moisture (in the air).

-

Usage

-

Between 0.3 l/m² and several l/m² depending on the type and condition of the substrate and the specific application

-

Apply to a large enough trial area to determine the precise amount required.

-

General information

-

Current regulations and legal requirements must be taken into account and deviations from these must be agreed separately.

The relevant test certificates must be observed when planning and carrying out work.

The level of absorption is crucial for the impregnation agent to work at its best. This depends on the respective pore volume and moisture content of the building material.

Carry out a quantitative analysis of aggressive salts if there are any salts present that could damage building materials.

High concentrations of harmful salts can cause major structural damage that impregnation cannot prevent.

Residue (e.g. surfactants, wax) from previous cleaning measures can have adverse effects on the treatment and must therefore be completely removed.

Application of restoration mortars, hydrophobizing primers and paints:

After application, the active ingredient "silicic acid ester" leads to a temporary water-repelling effect that disappears during the course of gel formation (reaction time: at least 28 days). Remmers Restoration Mortar, Funcosil impregnation agents and paints can be applied only after the gel formation is completed. If strengthened surfaces still show a water-repelling effect after more than 4 weeks reaction time, this can be suppressed by wetting the surface with alcohol or de-tensioned water.

-

-

Disposal instructions

-

Dispose of contents/container in accordance with local/regional/national/international regulations.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-