Article No. 040630

Quick-setting preparatory mortar

Product specifications

On delivery

aggregate according to DIN EN 13139

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Preparation of the substrate before applying mineral-based renders

- Equalising differences in the absorption properties of the substrate

Properties

- Good adhesion to the substrate

- Fast setting

- Ready for next coat after 90 minutes

- High sulphate resistance and low active alkali content (SR/NA)

-

Preparation

-

Substrate requirements

Clean, dust-free and capable of supporting a load.

-

Preparations

Pre-wet absorbent substrates so that they are slightly damp.

-

-

Application

-

Absorbent substrates

Apply SP Prep rapid as adhesive bridge (coverage area 50-70% opaque) at a layer thickness of max 5mm.

Weakly absorbent substrates

Fully cover the surface with SP Prep rapid (100%) in a layer thickness of max. 5 mm.

Mineral waterproofing slurry substrate

Apply a contact layer of mineral waterproofing slurry, and apply SP Prep rapid with full coverage (100%) and max. 5 mm layer thickness on the bonding layer while it is still wet.

-

Application instructions

-

Once it has hardened, mortar must not be made workable again by adding either water or more wet mortar.

Do not use the material to level out uneven surfaces.

Apply plaster after 90 minutes.

Improve the adhesion on smooth and dense surfaces using ZM HF [basic] .

-

-

Working tools / cleaning

-

Mixing tool, trowel, steel broom, render coating sprayer, hopper gun

Clean tools with water while the material is still fresh.

-

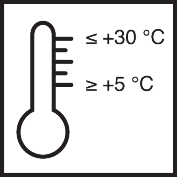

Storage / shelf life

-

If stored in an unopened container and in a dry place, the product will keep for approx. 12 months.

-

Usage

-

Full coverage 4 – 6 kg/m²

-

Apply to a large enough trial area to determine the precise amount required.

-

General information

-

May contain traces of pyrite (iron sulphide).

Do not use on gypsum-based substrates.

The mixing water must be of drinking water quality.

Low chromate content in accordance with Directive 2003/53/EC.

Always set up a trial area/trial areas first.

Current regulations and legal requirements must be taken into account and deviations from these must be agreed separately.

The relevant test certificates must be observed when planning and carrying out work.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-

![ZM HF [basic] ZM HF [basic]](https://m.remmers.com/gebindeabbildungen/2400w/52838.png?w=100&version=1)