Article No. 637106

Water-based, pigmented, matt sealant

Product specifications

On delivery

Component A

Component B

Mixture

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Sealant in Remmers Water Vapour Diffusion-Open systems

- Topcoat on Remmers Water Vapour Diffusion-Open blinded coatings

- Topcoat in the system Remmers Deck OS 8 WD-LE

Properties

- Matt

- Low emissions

- Can be given non-slip properties

- Water vapour diffusion capable

- Coating compatibility test

- Contains no plasticisers, nonylphenols or alkylphenols

- Physiologically harmless once fully cured

-

Preparation

-

Substrate requirements

The substrate must be firm, dimensionally stable, capable of bearing loads and free of loose constituents, dust, oil, grease, rubber marks and other substances that could interfere with adhesion.

The substrate must be prepared using suitable Remmers Water Vapour Diffusion-Open products.

For OS 8 systems, please see the corresponding test certificate.

-

-

Preparation

-

Combination container

Add the entire quantity of the hardener (component B) to the base compound (component A).

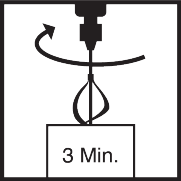

Mix thoroughly with a slow-speed electric mixer

(approx. 300 - 400 rpm).Pour the mixture into a separate container and mix again thoroughly.

Mix for at least 3 minutes.

Insufficient mixing is indicated by streaks forming.

-

Application

-

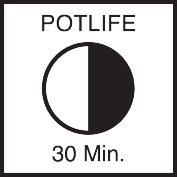

The times given are reduced at higher temperatures and increased at lower temperatures, in particular in combination with high humidity.

-

Working tools / cleaning

-

Toothed trowel, smoothing trowel, brush, epoxy roller and mixing apparatus

-

More detailed information can be found in the Remmers Tool Programme.

Clean tools, equipment and any splashed material immediately with water while still fresh.

Take suitable protective and waste disposal measures when cleaning.

-

Storage / shelf life

-

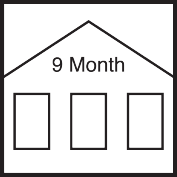

If stored in unopened original containers in a cool, dry and frost-free place, the product will keep for min. 9 months (component A) or 24 months (component B).

-

Usage

-

See application examples

-

-

Application examples

-

S

Pour the material generously onto the surface. Use a suitable tool, e.g. a rubber scraper, to distribute the material, then roll using an epoxy roller.

approx. 0.15-0.25 kg/m² binder per coat

-

HS

Pour the material generously onto the surface. Use a suitable tool, e.g. a rubber scraper, to distribute the material, then roll using an epoxy roller.

Multiple layers must be applied. Dilute the resin mixture for the first application with 5% by mass of water.

approx. 0.60-0.80 kg/m² binder in two coats

-

-

General information

-

Unless otherwise specified, all of the values and application rates given above have been determined under laboratory conditions (20 °C) using standard colours. Slight deviations from these values may arise if the product is worked with on site.

When coating continuous surfaces, only use materials with the same batch number as slight differences in colour, gloss and texture may occur.

When repairing surfaces or working up to existing surfaces, there will be a visible transition in appearance, texture and degree of gloss.

Shades of colour with low hiding power (e.g. yellow, red or orange) tend to have a translucent effect on the subsequently applied sealant. In such cases, a colour-coordinated construction, e.g. light grey, is necessary.

The sealant has a slightly textured surface typical for this type of system.

In order to achieve even surfaces, appropriate allowances for roughness depth must be taken into consideration.

Abrasive mechanical loads leave traces of wear.

Suitable for vehicle traffic with rubber tyres; not suitable for vehicle loads with metal or polyamide tyres nor for dynamic point loads.

Epoxy resins are generally not colourfast when exposed to UV light or weather.

The colour stability of the sealant can be improved by using a UV-absorbent polyurethane sealant.

Observe the corresponding test certificate for OS 8 systems.

Further notes on working, system construction and maintenance of the listed products can be found in the latest Technical Data Sheets and the Remmers system recommendations.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For professional users only!

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet and the brochure entitled "Epoxy Resins in the Construction Industry and the Environment", issued by Deutsche Bauchemie e.V. (3rd edition 2022).

-