Article No. 049125

Undercoat render based on NHL 5

Product specifications

On delivery

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Undercoat render for repair, renovation and restoration of old building facades, historical buildings and architectural monuments

- Levelling out substrates

Properties

- Cement-free

- Low-stress hardening behaviour

- Low modulus of elasticity

- Moisture- and climate-regulating

-

Preparation

-

Substrate requirements

Clean, dust-free and capable of supporting a load.

-

Preparations

Substrate: absorbent with low strength

Apply product as a bonding layer > 50% opaque.

Substrate: weakly absorbent

Apply product as a scratch coat (contact layer).

-

-

Application

-

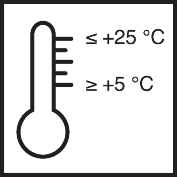

Application requirements

Temperature of the material, air and substrate: from min. +5 °C to max. +30 °C

-

One-layer

Apply the product using a suitable tool.

Single layer thickness: 10 - 20 mm

Two-layer

Single layer thickness: 10 - 20 mm

Roughen the first layer with a render comb.

Apply second layer once sufficiently dry.

Level off surface with a long float.

Use a render comb to roughen horizontally in preparation for the next layer of render after setting.

-

Application instructions

-

Once it has hardened, mortar must not be made workable again by adding either water or more wet mortar.

On critical substrates (highly uneven, fissured, mixed masonry) we recommend incorporating the reinforcement fabric in the upper third of the restoration render.

Apply additional diagonal reinforcement to the edges of building openings.

Protect wet mortar surfaces against frost, rain and drying out too quickly for at least 4 days.

Hairline/shrinkage cracks are safe and are not cause for complaint as they do not impair the properties of the mortar.

-

-

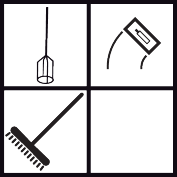

Working tools / cleaning

-

Mixing tool, fine plastering trowel, smoothing trowel, broom

Clean tools with water while the material is still fresh.

-

Storage / shelf life

-

If stored dry in closed containers, the product will keep for approximately 9 months.

-

Usage

-

Approx. 1.9 kg/m²/mm

-

Apply to a large enough trial area to determine the precise amount required.

-

General information

-

The mixing water must be of drinking water quality.

May contain traces of pyrite (iron sulphide).

Do not use on gypsum-based substrates.

The characteristic data of the product were calculated under laboratory conditions at 20°C and 65% relative humidity.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-