Article No. 2773201

Acrylic dispersion with special additives, free from plasticisers

Product specifications

On delivery

Once fully cured

Once fully cured

100% (DIN EN ISO 8339) Approx. 0.8 N/mm²

(DIN EN ISO 8339) Approx. 150%

(DIN EN ISO 10563) Approx. 25%

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- For sealing narrow torn, cut and mitre joints in woodworking and window construction

- For use by professionals

Properties

- Very high solid content: Low shrinkage & early resistance against dry cracks

- Easy to apply

- Can be overcoated with conventional water-based varnish and stain systems

- Dries to form a transparent film

-

Preparation

-

Substrate requirements

Joint sides must be clean, dry, free from grease and capable of bearing a load.

Use on the primer or intermediate coat.

-

Preparations

Preliminary trials are generally advised in order to optimise the workflow and waiting times.

-

-

Application

-

Cut off tip at an angle according to the width of the joint and inject, filling the joint completely.

Apply the material with sufficient pressure to the sides of the joint, then smoothen with a moist spatula.

Avoid applying an excess of the fresh compound.

Use a suitable tool or finger cot to level off the filler.

-

Application instructions

-

Do not use in connection or expansion joints.

The product is not recommended for contact with solvent-based coatings.

-

Drying

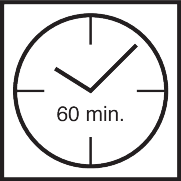

Drying time (2 x 2 mm joint)

Approx. 60 minutes (+23 °C/50% RH)Low temperatures, poor ventilation and high humidity delay drying.

-

Working tools / cleaning

-

Sealant gun, Fensterfix scraper

-

Cleaning with water directly after use or with Aqua RK-898-Cleaning Concentrate for persistent contamination.

-

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 12 months.

-

Usage

-

Approx. 5 ml/running metre for a 2 x 2 mm joint cross-section

-

General information

-

Glued joints must be produced properly until glue is discharged over the entire surface area in accordance with the glue manufacturer's instructions.

When applying a subsequent coating on Induline A-920, the layer must not be made too thick. The layer thicknesses specified in VFF Leaflet HO.03 must be observed.

On large-pored wood, we recommend sealing with Induline A-920 after applying the intermediate coating.

Current regulations and legal requirements must be taken into account and deviations from these must be agreed separately.

The relevant test certificates must be observed when planning and carrying out work.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-