Article No. 688083

Pigment paste

Product specifications

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Part of the Remmers Metalufloor System

Properties

- Configured for 10 kg units of binder

- For floors with special visual effects and a unique appearance

-

Preparation

-

Substrate requirements

The substrate must be firm, dimensionally stable, capable of bearing loads and free of loose constituents, dust, oil, grease, rubber marks and other substances that could interfere with adhesion.

-

Preparations

The substrate must be pre-treated with Epoxy Primer PF in silver grey.

-

-

Application

-

Application requirements

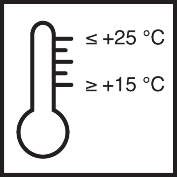

Temperature of the material, air and substrate: from min. +15 to max. +25 °C

-

As a general principle, higher temperatures will reduce and lower temperatures will increase the times stated.

-

Working tools / cleaning

-

2.5 mm Remmers floor finish scraper, toothed trowel (ZL 55), mixer

-

More detailed information can be found in the Remmers Tool Programme.

Clean tools, equipment and splashed material immediately while fresh with V 101.

Take suitable protective and waste disposal measures when cleaning.

-

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 24 months.

-

Usage

-

3% by mass, based on the binder

-

-

Application examples

-

C

Pour the material onto the prepared surface and spread using a 2.5 mm Remmers layer thickness trowel or toothed trowel (ZL 55).

Monitor the application rate throughout the process to ensure that it is complied with.

After leaving to stand for a brief period, use a smoothing trowel to create the desired effect.

The time at which smoothing is carried out will determine the visual appearance (cloud formation). This must be kept constant throughout the application period.

Surfaces must be sealed with suitable Remmers products.

Min. 2.7 to max. 3.0 kg/m² of the prepared mixture

-

-

General information

-

Unless otherwise specified, all of the values and application rates given above have been determined under laboratory conditions (20 °C). Slight deviations from these values may arise if the product is worked with on site.

The overall appearance of the floor is heavily influenced by the finishing techniques used and the conditions on site.

Every floor is unique and cannot be reproduced.

Surfaces must be sealed with suitable Remmers products.

In case of repairs on the surface or working up to existing surfaces, there will be a visible transition in appearance and texture.

Abrasive mechanical loads leave traces of wear.

Suitable for vehicle traffic with rubber tyres; not suitable for vehicle loads with metal or polyamide tyres nor for dynamic point loads.

It is recommended to use polycarbonate mat underlay in office spaces.

The construction site conditions and the level of workmanship may differ from those present when the sample was created.

Further notes on working, system construction and maintenance of the listed products can be found in the latest Technical Data Sheets and the Remmers system recommendations.

-

-

Safety / regulations

-

For professional users only!

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet and the brochure entitled "Epoxy Resins in the Construction Industry and the Environment", issued by Deutsche Bauchemie e.V. (3rd edition 2022).

-