Article No. 073601

Pourable, two-component silicone casting compound that cures at room temperature

Product specifications

On delivery

Component A

Component B

Mixture

Once fully cured

Once fully cured

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Casting of high-value original pieces with accurate detail

- Production of solid and main moulds

- Forming with strong undercuts

Properties

- High reproduction accuracy and detail reproduction

- Excellent resilience

- Very good elasticity and tear resistance

- Good flow properties

- Easy demoulding

-

Preparation

-

Substrate requirements

The substrate must be clean, dust-free and dry.

-

-

Application

-

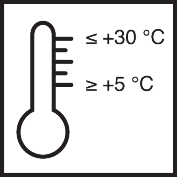

Application requirements

Temperature of the material, air and substrate: from min. +5 °C to max. +30 °C

-

Pour or apply by brush

Reaction time approx. 20 hours

-

Application instructions

-

The addition of up to 1% by mass of Thickening Additive AFM (0738) can increase the viscosity until stability is reached.

To ensure that the vulcanised material is completely free of bubbles, degas the silicone/hardener mixture in a vacuum prior to use (max. 5 minutes at 10-20 mbar).

Pourable resins, such as polyesters and polyurethanes, limit the ability to take a large number of impressions due to their aggressive nature.

When making impression of critical substrates, e.g. materials that are porous, silicate-based or moisture-absorbing, use a silicone-free releasing agent (e.g. wallpaper paste).

When creating supporting moulds, a suitable release agent must be applied to the outer skin of the silicone mould, e.g. Framework Paste (1121).

-

-

Working tools / cleaning

-

Paintbrush, spatula, stirrer

-

Clean tools immediately after use with thinner and brush cleaner.

Pull off any cured residue.

-

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 12 months.

-

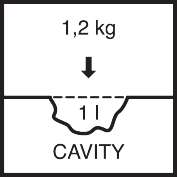

Usage

-

Approx. 1.2 kg/m²/mm layer thickness

-

General information

-

Current regulations and legal requirements must be taken into account and deviations from these must be agreed separately.

The relevant test certificates must be observed when planning and carrying out work.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-