Article No. 776405

System product/primer under Remmers 2K floor coating and PU garage coating

Product specifications

On delivery

Mixture

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- Primer/bonding layer under 2K floor coating and PU garage coating

- Bonding layer on load-bearing, sanded old epoxy coatings and ceramic coverings

Properties

- Water vapour diffusion capable

- Water-dilutable

- Excellent adhesion on many substrates

- Mix with anti-slip additives for a non-slip finish

-

Preparation

-

Substrate requirements

The substrate must be firm, dimensionally stable, capable of bearing loads and free of loose constituents, dust, oil, grease, rubber marks and other substances that could interfere with adhesion.

Substrates must have reached their moisture balance and must also be protected against moisture penetration from the reverse side, including during use.

Suitable substrates are concrete (C ) and cement screed (CT), load-bearing, rigid EP coatings indoors. Furthermore, it may also be possible to seal load-bearing ceramic tile coverings, anhydrite screeds and hard asphalt screeds. In these cases, however, the Remmers Technical Service (RTS) should be consulted.

-

Preparations

Concrete or cement screed substrates must be prepared by sanding with a disc sander fitted with suitable abrasives. Prepare the edges along rising components by grinding with a concrete grinder. Old coatings or ceramic tile coverings must be prepared using diamond grinding technology. Finally, all dust must be removed from the substrate.

-

-

Preparation

-

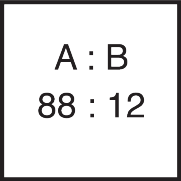

Combination container

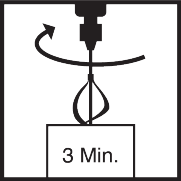

The two components (A and B) are supplied in coordinated containers. Add component B to component A. Ensure that the hardener container (component B) is emptied completely.

Then mix intensively with a suitable mixer and mixing paddle until no more streaks are visible. A minimum mixing time of 2-3 minutes must be observed. Pour the premixed material into an additional container (e.g. clean paint bucket) and mix again briefly.

On higly absorbent substrates the product can be diluted with water up to 10 % by mass.

To make the sealing system slip-resistant, add the product Anti-Slip Additive in a ratio of 2.5% and mix in thoroughly. This corresponds to adding 125 g (half a container) to a 5 kg 2K floor coating or 2K epoxy primer.

-

Application

-

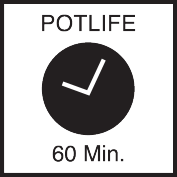

The times given are reduced at higher temperatures and increased at lower temperatures, in particular in combination with high humidity.

-

Working tools / cleaning

-

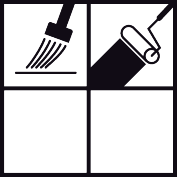

Epoxy roller 10 and 25 cm, paintbrush and suitable mixer

-

More detailed information can be found in the Remmers Tool Programme.

Clean tools, equipment and any splashed material immediately with water while still fresh.

Take suitable protective and waste disposal measures when cleaning.

-

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 12 months.

-

Usage

-

approx. 0.15 - 0.25 kg/m² material per coat (depending on the substrate)

-

-

Application examples

-

P

Apply the ready-to-use mixture evenly, e.g. using a Remmers epoxy roller (25 cm) and roll crosswise. Puddle formation must be avoided. Apply the material with a suitable flat brush and 10 cm epoxy roller along rising components, in hard-to-reach areas and corners. In the case of highly absorbent substrates, it may be necessary to apply several layers.

Priming:

Approx. 0.15 - 0.25 kg/m² material per coat (depending on the substrate)

Slip-resistant priming:

Approx. 0.15 - 0.25 kg/m² material per coat (depending on the substrate) plus 2.5% non-slip additive

-

-

General information

-

Primers must always be applied so that all pores are filled; it may therefore be necessary to increase the application rate or to apply a second coat.

Wetting problems are possible on non-absorbent or slightly hydrophobic substrates. In this case, the priming must be repeated a second time.

The end of the pot life cannot be recognised by increased viscosity or temperature, thus the max. working time must be strictly observed.

Abrasive mechanical loads leave traces of wear.

Epoxy resins are generally not colourfast when exposed to UV light or weather.

Read the application instructions before use. Recommended for professional users.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet and the brochure entitled "Epoxy Resins in the Construction Industry and the Environment", issued by Deutsche Bauchemie e.V. (3rd edition 2022).

-