Article No. 715101

Water-based natural effect varnish for dimensionally stable wood building elements with direct or indirect exposure to weather

Product specifications

On delivery

The stated values represent typical product characteristics and are not to be construed as binding product specifications.

Field of application

- For all dimensionally stable wood building elements made of light-coloured softwood and hardwood

- Windows, exterior doors & conservatories

- Wood-aluminium composite structures

- Post-rail constructions

- Natural colours for surfaces exposed to direct weathering – clear version for protected constructions

- Intermediate and finishing coats

Properties

- Cloth matt surface with very little emphasis of grain: the treated wood has a natural looking finish

- UV absorbers reduce darkening of the wood

- Added bonus of being resistant to scratches and hand cream when surface is subjected to normal use

- Surfaces do not become shiny

- Clear version of the product for protected constructions provides the best possible natural look

- Natural colours for surfaces exposed to direct weathering: pigmented versions of the product are available for the different types of wood so as to provide a natural look with good UV protection

-

Preparation

-

Substrate requirements

The substrate must be clean, dry, free of dust, grease and loose substances, and prepared in the correct manner.

Dimensionally stable wood building elements: wood moisture content 11-15%

-

Preparations

Thoroughly remove any dirt, grease and non-adhering old coatings.

Thoroughly sand any old coatings that are still intact.

Sand grey and weathered wood surfaces down to sound, bright wood.

Observe BFS Code of Practice No. 18 "Coatings on Wood and Wooden Working Materials in Outdoor Areas".

Pre-treat exterior wood that is to be protected from soft rot and/or blue stain with Aqua IG-15* or Aqua HSL-35* - not necessary for interior wood (*Use biocides safely. Always read the label and product information before use).

-

-

Application

-

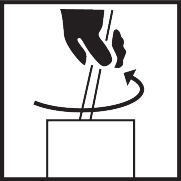

Stir well.

Apply using a brush or roller.

Apply a second coat once the first has dried.

See application examples for precise system configuration.

Seal opened containers well and use contents as soon as possible.

-

Application instructions

-

Check colour and compatibility with the substrate by applying a trial coat.

Before coating technically modified woods and wood-based materials, apply the product to a trial surface and conduct a suitability test on the desired area of use.

Prior to full application, please apply a test coat to a sample area under practical conditions using the desired system, then test or examine the surface properties.

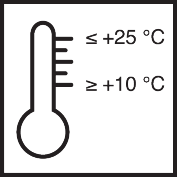

Do not use at temperatures below +5°C.

If the temperature is too low or the humidity too high, it will take longer for the material to reach the desired properties.

If the temperature is too high or the humidity too low, the material will dry more quickly. In such cases, we recommend adding Aqua OZA-90 Open Time Additive.

Carry out light intermediate sanding on particularly elegant surfaces prior to applying a finishing coat.

Observe the waiting times between coats.

Substances in oak may bleed, causing dark discolouration, when coated with water dilutable dispersion stains.

Examine sealants, sealing material and foreign materials for their coating compatibility.

Closed-pore varnishing must be carried out.

-

Drying

Practice values at +20 °C and 65% relative humidity.

Low temperatures and high humidity delay drying.

-

Working tools / cleaning

-

Acrylic brush, microfibre paint roller

-

Clean tools with water or Aqua RK-898 Cleaning Concentrate immediately after use.

Ensure that any residue from cleaning is disposed of correctly.

-

Storage / shelf life

-

If stored unopened in its original container in a cool, dry place and protected against frost, the product will keep for at least 24 months.

-

Usage

-

60 - 80 ml/m² per coat

-

Project-specific deviations should be determined by way of a trial coating.

Depending on the processing method, wood type and wood surface.

-

Application examples

-

Protected constructions:

Wood type oak, clear: Aqua HSL-35/m* farblos, 2x Aqua NEL-56/tm clear

Wood type spruce, clear: Aqua HSL-35/m* FT 38863, 2x Aqua NEL-56/tm clear

Wood type larch, clear: Aqua HSL-35/m* farblos, 2x Aqua NEL-56/tm clear

Direct exposure to weather:

Wood type oak, natural oak: Aqua HSL-35/m* FT 38854, 2x Aqua NEL-56/tm FT 38855

Wood type spruce, natural spruce: Aqua HSL-35/m* FT 38856, 2x Aqua NEL-56/tm FT 38857

Wood type larch, natural larch: Aqua HSL-35/m* FT 38858, 2x Aqua NEL-56/tm FT 38859

The colours are matched to the respective wood type, but can also be used on other wood types. The colour finish will then deviate from the colour sample.

-

-

General information

-

Care and maintenance:

Wood is subjected to great climatic and environmental stresses when outdoors. The coat is susceptible to the processes of natural ageing, wear and decomposition. Decomposition takes place at different speeds, depending on the stress (weak, average, strong) placed on the wood building element. Weathering stages may vary according to the part or element affected. To give wood the longest and best possible protection it is advisable to examine surfaces every year. Any damage found should be addressed immediately after cleaning.

For cleaning and care, we recommend the care set for doors (2746).

Using the care balsam contained in the set can help to extend the intervals at which maintenance is required, while retaining the uniform, cloth matt surface.

On planed larch and softwoods with a high resin content, the coating may have reduced adhesion and resistance to weathering. This is especially the case on horizontal year rings, knots and areas of winter growth that are high in resin. Maintenance must be carried out more frequently on these surfaces.

The only remedy for this is pre-weathering or very coarse sanding (P80).

If these wood types are rough-sawn, considerably longer maintenance intervals are to be expected.

-

-

Disposal instructions

-

Larger quantities of leftover product should be disposed of in the original containers in accordance with the applicable regulations. Completely empty, clean containers should be recycled. Do not dispose of together with household waste. Do not allow to enter the sewage system. Do not empty into drains.

-

-

Safety / regulations

-

For further information on the safety aspects of transporting, storing and handling the product and on disposal and environmental matters, please see the current Safety Data Sheet.

-